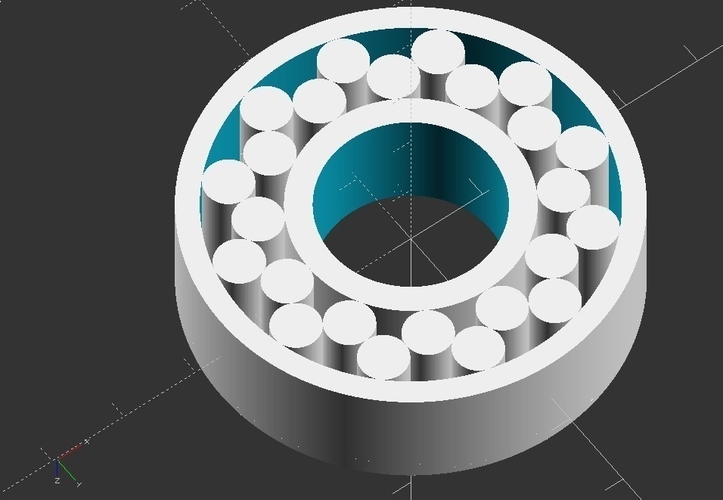

Cageless Roller Bearing

pinshape

Summary This design simplifies assembly compared to my previous cageless bearing project. Although it's not entirely cageless since rollers need constraint, 45° angled rollers make it relatively easy to manufacture with a frictionless fit. This is just a proof of concept; I used 0.2 tolerance for the mounting aid and printing is underway. UPDATE: I realize now that more spacing was needed. The inside and outside parts fit over the rollers on the mounting plate, but don't align properly due to slightly offset pins. Achieving a press fit requires precise adjustment - please inform me if you've successfully dialed it in. UPDATE 2: I corrected an error by adding tolerance to the outer ring after printing. Measured corrections were made to improve fit theory-wise. Note that a radius deviation of 0.1195 led to roller collapse during measurement. UPDATE 3: When loaded, rollers at the bottom are pushed outward, forcing those above together. This suggests that for the concept to work, a 45° roller angle is optimal since it minimizes movement-induced roller constellation collapse when not spinning. To print, flip this design 180 degrees; I used 6x14mm dowel pins as rollers. Unfortunately, customizer issues prevent loading attached libs, making this design non-functional. Shortcut functions and other libs are courtesy of OpenSCAD master parkinbot.

With this file you will be able to print Cageless Roller Bearing with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Cageless Roller Bearing.