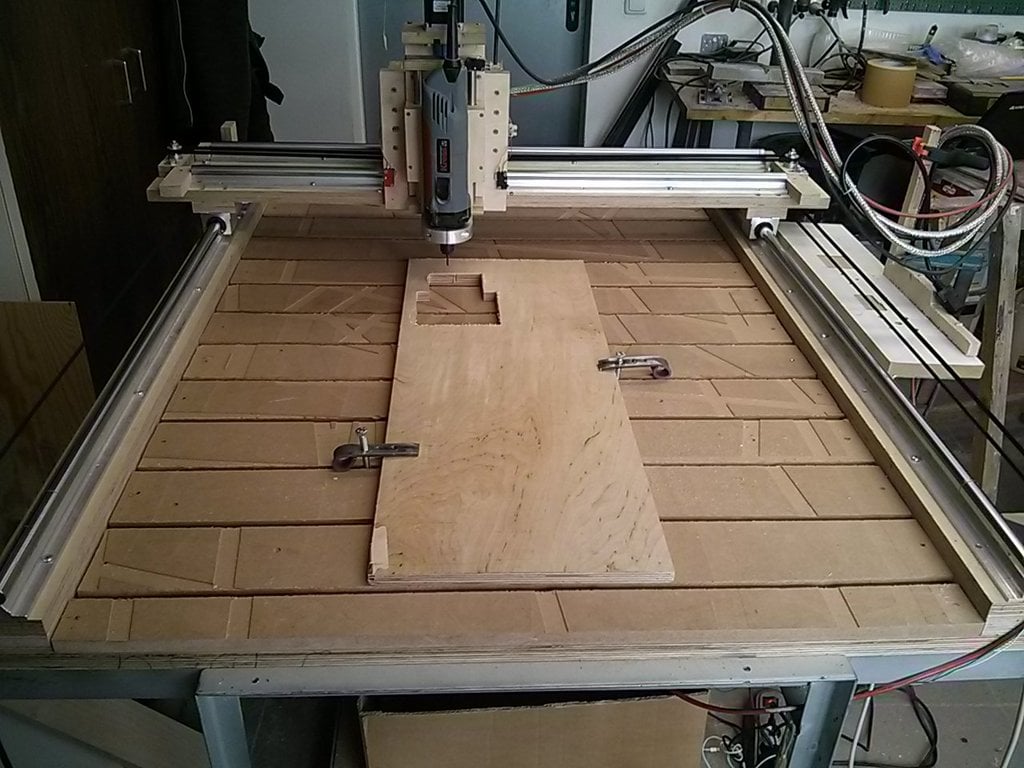

Budget-CNC Mill

thingiverse

Build your own CNC machine that offers maximum value for money! Be cautious, though - this is a beta version! The prototype has been running non-stop for around 1000 hours now. So far, the following parts have needed replacement: * Z-Axis-Ball-bearing failed and had to be replaced at about 400 hours (costing approximately 50 cents) * The belt required swapping out at roughly 700 hours (a cost of around 15 euros) * I added fans to enable motors to run at full current (approximately a 10-euro investment) * Ballbearings needed readjustment at about 400 hours This CNC machine can handle large-scale projects, scaling up to 2 meters by 2 meters depending on the size of the chosen rails. I'm currently using 120x100cm rails (Y/X). If you plan to use rails larger than 120cm in length, you might need to add some extra reinforcement! The CNC machine uses NEMA23 Steppers at a voltage of 36V. Here are its key specifications: * Working Speed: up to 4000mm/min * Moving Speed: 6000mm/min * Spindle: Kress 1050 FME This machine is capable of dealing with aluminum, achieving precision levels of around 0.07mm (cutting depth of 0.2mm // sideways accuracy of 0.1mm). Here's a breakdown of the Bill of Materials: * Rails: sourced from http://www.cnc-discount.de (also available on AliExpress) * Stepper Motors: 3x Nema23, 3A * Power Supply: 36V / 350W * Stepper Drivers: DM542+ * Note: The stepper motor, driver, and power supply can be purchased as a kit for approximately 190 euros. * Old PC with LinuxCNC (Dell Optiplex 745; sourced from lapstore.de for around 40 euros) * Ballbearings: 608zz * GT2-Timing Belt with steel core (AliExpress) * A multitude of screws and nuts in various sizes (available online, sourced from schraubenking.at) * Z-Axis: You can either build one yourself (requires a CNC machine and some experience; template included in the plans) or purchase a pre-made one from this seller on eBay ("cnc z-achse" by flohmarkt4u) * Cables (stepper, endswitches) * Endswitches (3x) * GT2-Pulleys - ensure you get ones specifically designed for Nema23 Steppers (6.35mm center-hole) * Wood: 24mm / 20mm Plywood / Multiplex This project is built upon the work of others, including the Parametric Coupler by David Bunch (available on Thingiverse at http://www.thingiverse.com/thing:724999).

With this file you will be able to print Budget-CNC Mill with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Budget-CNC Mill.