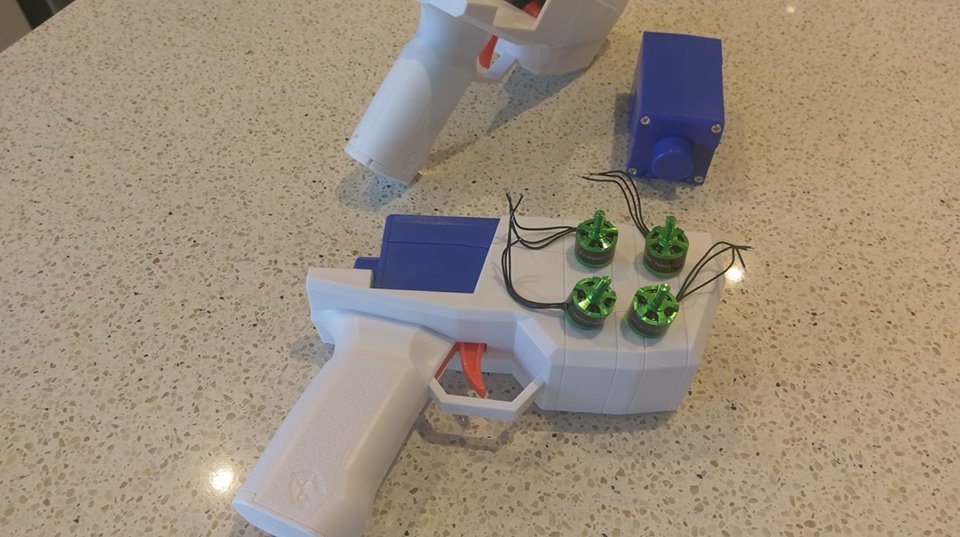

Brushless Dual Stage Worker Hurricane Cage + Flywheels

thingiverse

Stock motors in a Worker Hurricane are quite weak. But now, you can upgrade them with a Brushless setup. Performance on 3s has low speeds of 190fps and high speeds of 215fps (averaging around the low 200's). Over time, an accumulation of dart foam on the flywheels will improve performance by about 5-10 fps. There are two crush versions of the wheel available. I am using 8.5, but if you have jamming issues with your darts, you can try using 9.0. **Shopping List:** 4 x Turnigy Viking 1308 4100kv motors (two CW and two CCW) https://hobbyking.com/en_us/multistar-viking-brushless-outrunner-drone-racing-motor-1308-4100kv-cw.html https://hobbyking.com/en_us/multistar-viking-brushless-outrunner-drone-racing-motor-1308-4100kv-ccw.html 1 x Brushless 4-in-1 Quadcopter ESC with a rating of 20a or more. It needs to be small, and I used this specific one. https://www.amazon.com/Brushless-Quadcopter-Escaper-ESCTimer-Programmer/dp/B078W8V5F7 The following shell mods are required: - Cut out all the motor support structures in the center of the lower shell piece. Obviously not the screw posts. - Remove the vertical support structures in the lower shell towards the front. There are three if I recall. - Cut out the barrel support on the top and bottom shell all the way until about 5mm before the front of the shell. - Cut off the barrel retention nubs on the top and bottom of the shell. The top and bottom assembly should seat neatly in the shell. - Cut some vents for the underside of the cage to be able to suck in outside air. Airflow is terrible in this shell. **Step-by-Step Instructions:** 1) Install motors 2) ESC goes between the lower shell and the lower cage. 3) Screw down the lower cage to the lower shell 4) Install flywheels 5) Install upper cage assembly. Use M2.5 bolts (or your choice of similar self-tapper) 6) Install arduino on top of upper cage assembly. Solder wires to the side, not through the holes. 7) BEC goes in the wiring run space Follow my photos for guidance. **Wiring:** - Rev trigger connects to Pin A2 (as labelled on the Arduino). The side of the switch connects to Ground. The stock arrangement with the slide switch can be used to break this signal to provide a safety. - Speed Pot center pin connects to Pin A0. One side of the Speed Pot connects to 5v from the BEC, the other connects to Ground - ESC Front connects to Pin 10 - ESC Rear connects to Pin 9 The solder pads for the power wires on the ESC are a little tight. Don't worry if some solder spills over to the surface mount caps - they are continuous. Don't let the solder spill over to anything else. **Video Info:** Demo https://www.youtube.com/watch?v=k1z1VuG1Bmo **Shoutouts:** Shoutout to Ultrasonic2 as I cut my teeth building a number of brushless setups based on his files. That experience allows me to develop this. **License:** Absolutely no commercial use of these models, firmware, circuit diagrams, etc are allowed. My exception is when you pay a general purpose print lab / service (such as 3dHubs) to print models for your own personal use. If you have anything else in mind, please contact me.

With this file you will be able to print Brushless Dual Stage Worker Hurricane Cage + Flywheels with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Brushless Dual Stage Worker Hurricane Cage + Flywheels.