Bowden extruder

thingiverse

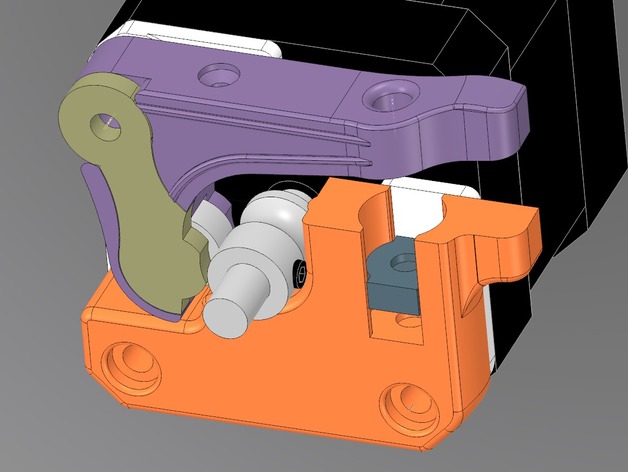

Bowden Extruder with Adjustable Filament Pressure allows for extrusion of semi-rigid filaments. The parts are designed to be printed without material support, utilizing free software DesignSpark Mechanical (.rsdoc file). Nonprintable Components include two M3 x 12 screws, one M3 x 18 screw functioning as a hinge for the tension arm, a 684ZZ ball bearing, a spring with 1 mm string diameter, 9 mm outside diameter, 7 mm inner diameter, and 22 mm height, an Allen head M3 x 16 screw, its nut, an M5 pneumatic connector, and one MK8 Drive Gear. Assembly Instructions: Attach the ball bearing to the tension arm cover shaft and assemble on the tension arm. Place the M3 nut in the small movable piece and screw it into place. On the base, attach the pneumatic connector, present the two fixing screws, position the spring tenders in their lodgings, and mount the MK8 drive gear on the motor shaft. Screw the base onto the motor plate, adjust the MK8 gear so its center is perfectly aligned with the filament guide hole of the base, place the spring tender in its lodging, place the spring above its tender, position the arm in place and screw it loosely so that it remains mobile. Tighten using an Allen key to set tension.

With this file you will be able to print Bowden extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Bowden extruder.