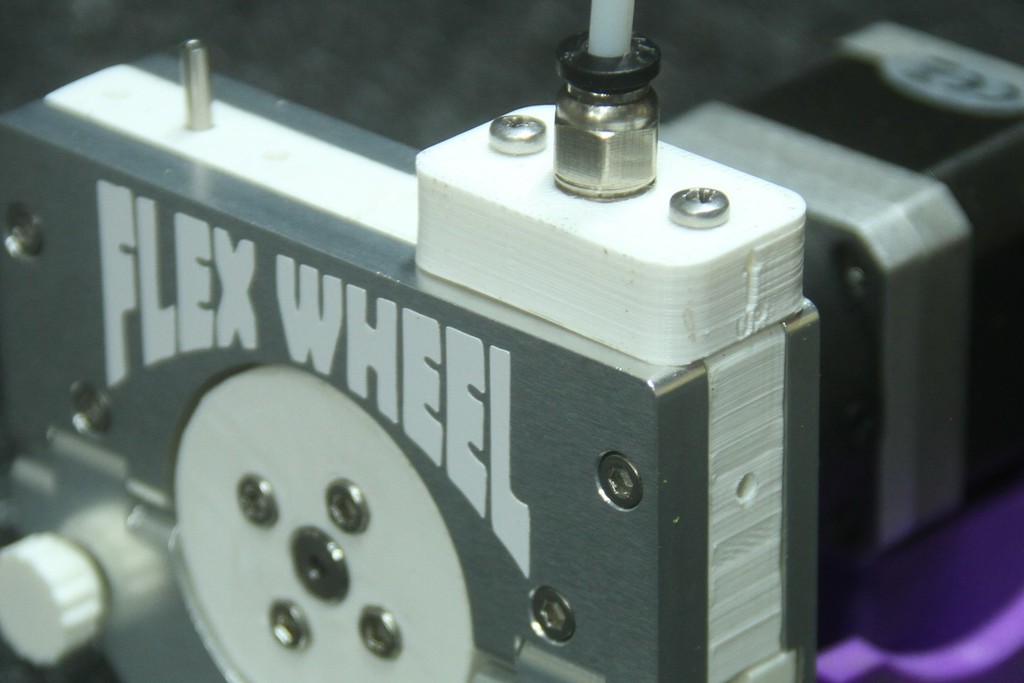

Bowden Coupling Block for Flex Wheel Extruder

thingiverse

Block for attaching Bowden tube coupling to the Flex Wheel. You can either thread with a 1/8 inch tap or if you don't have the tap, use your coupling to make the thread. If doing it this way, it may help while the piece is sitting on the warm heat bed directly after printing. Attach the block to the Flex Wheel's body using two M3 x 16mm screws. Files are provided for 1.75 mm or 3 mm filament size Flex Wheel Mods (there is a slight difference). Mount with the arrow located towards the outside edge and facing up. Ideally, use a coupling that allows the PTFE tube to be pushed all the way through. Being able to push the tube through the coupling eliminates small cavities in critical areas, such as where the drive system meets the tube and where the tube meets the hot end. A good quality coupling with a collet that releases its grip on the tube when pressed allows for easy length adjustment of the tube, ensuring no gaps exist. For printing true flex through a Bowden Tube, create a seamless transition from the Flex Wheel to the PTFE tube. Carefully use a 3 mm bit (1.75mm) or a 4 mm bit (3mm) drill approximately 5mm into one end of the tube. Fit the PTFE tube snugly over the stainless filament outlet tube of the Flex Wheel, mount block and coupling. Several pictures are attached to demonstrate what is meant. More information can be found at https://flexwheelextruder.com.

With this file you will be able to print Bowden Coupling Block for Flex Wheel Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Bowden Coupling Block for Flex Wheel Extruder.