BNBSX Short Ears MK3S Extruder

thingiverse

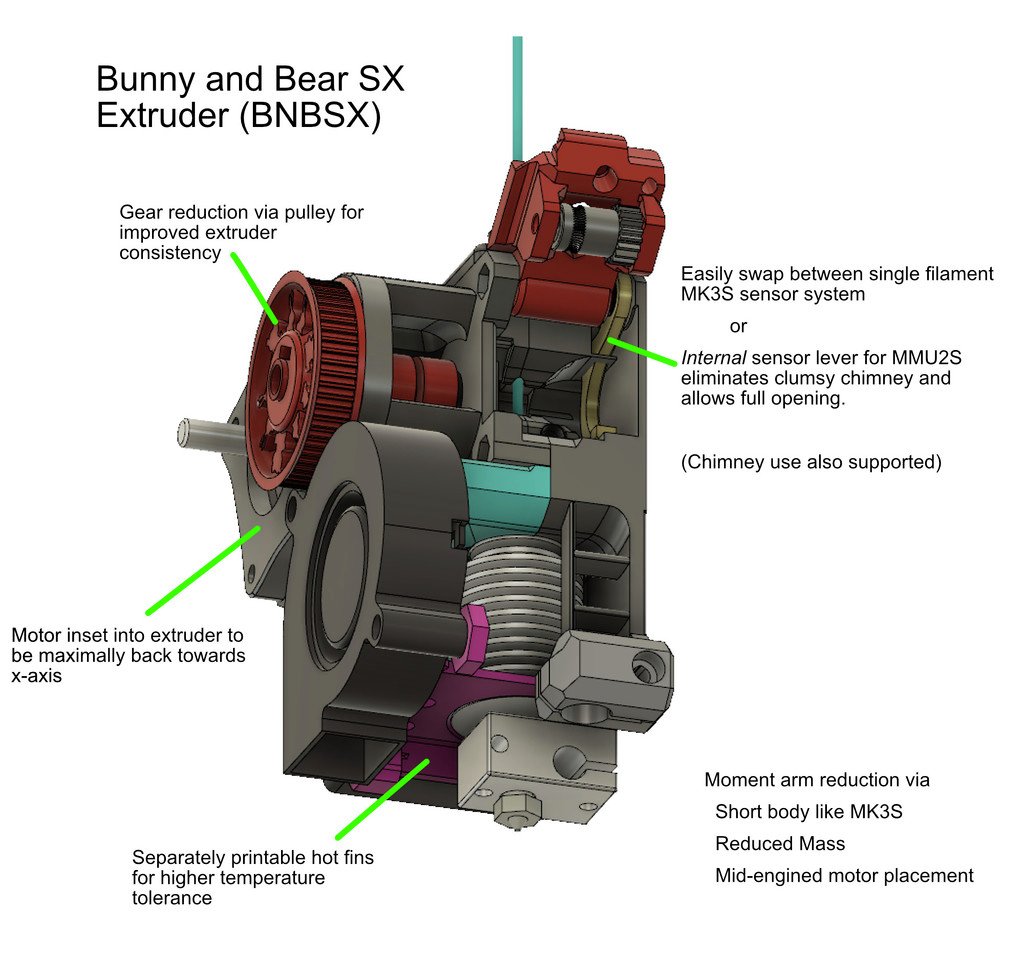

It appears you've provided a detailed set of instructions and notes related to a 3D printer project, specifically the Mosquito hot end and x-end assembly. The text includes settings for G-code commands, specific details about motor wiring, and various upgrades and modifications made to the original design. Here are some key points summarized: 1. **Motor Wiring**: The motor must be wired in reverse due to a specific requirement of the Einsy board. This is achieved by plugging the motor into the Einsy upside down. 2. **Microstepping and E-Steps Settings**: These settings depend on the type of stepper motor used (1.8 degrees or 0.9 degrees). The instructions provide the correct G-code commands for both types, including M350 for microstepping and M92 for setting the number of steps per unit length. 3. **Pulley Gear and E-Steps Settings**: There's a specific pulley gear inspired by Skelestruder that requires different e-steps values based on whether it's the 54-tooth or 56-tooth version. 4. **Print Fan Adjustment**: A common issue is the fan bolt tab contacting the drive belt, which can be resolved by shaving off some plastic from the bolt tab using an X-acto knife. 5. **Bearing Pressing Aid and Reinforcement of Motor Plate**: There are specific modifications to make the motor plate more durable and easier to work with bearings, including the addition of a bearing pressing aid. 6. **Upgrade List (Recent Change Log)**: This section lists various upgrades made to the design over several iterations, including changes to the PINDA mounting clamp, extruder main and extruder E3D pane, x-end idler, pulley gear, motor plate gearbox prints, fan shroud, bearing pockets, and more.

With this file you will be able to print BNBSX Short Ears MK3S Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on BNBSX Short Ears MK3S Extruder.