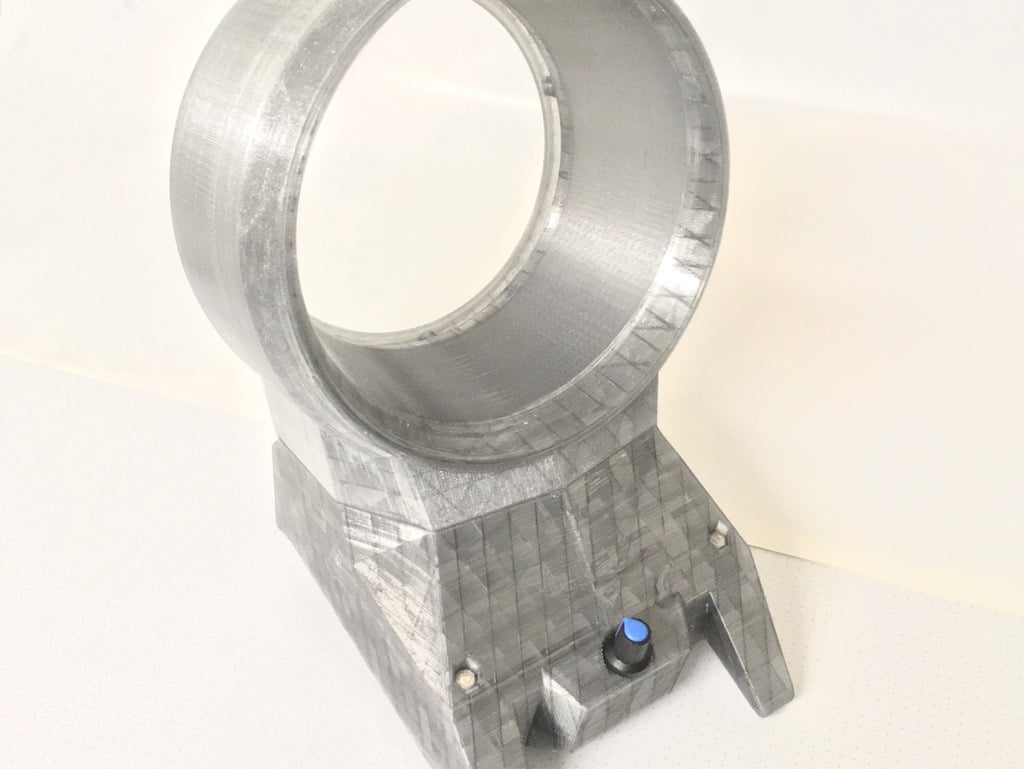

Bladeless Fan

thingiverse

I am intrigued by the prospect of creating a bladeless fan powered by a 120xx fan. I wonder if an Air Amplifier fan can produce more airflow than its original counterpart. To find out, I decide to build one myself. I choose the 12038 fan because it is capable of generating more airflow at lower RPMs, resulting in less noise pollution. The 12025 fan is also a viable option. The adjustable angle feature is achieved by means of a large screw located behind the fan. If your printer has difficulty printing the screw hole, you can opt for the "04.1 ANGLE ADJUSTING SCREW_LOOSE" version instead. Support structures are required for the 01 LOWER HOUSING, 02 UPPER HOUSING, and 05 GRILL components. The bill of materials includes: 1. Files 01-05 2. Multiple segments of 1.75mm filament, each approximately 8mm long, serving as locator pins 3. One 12038 or 12025 fan 4. One DC plug socket 5. One PWM DC Motor Governor 6. Wire 7. Four M4x50 bolts and nuts Before assembly, it may be necessary to enlarge the locator holes using a 1.8mm drill. If the pins fit snugly, gluing may not be required. Ultimately, the entire system generates too much pressure drop, resulting in airflow that appears less than the original fan. Perhaps I should attempt to create larger gaps around the ring.

With this file you will be able to print Bladeless Fan with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Bladeless Fan.