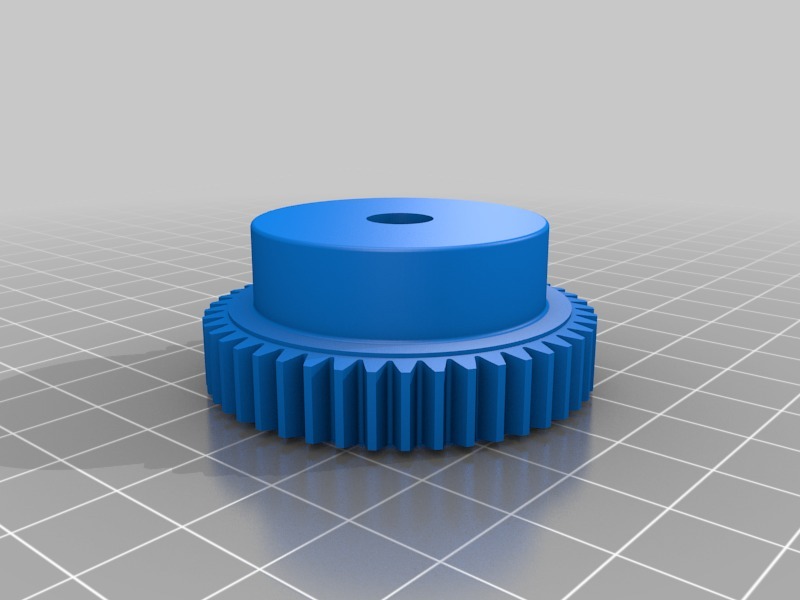

Better 3D Printed Gears

thingiverse

This is how I conquered 3D printing decent spur gears. Have you ever printed gears only to struggle with filing out the spread where the part has been set on the printer bed? Do you find it challenging to release the part from the bed without damaging the gear teeth? The first thing I did was to modify the original gear file, imported from the McMaster site in Fusion360, by creating a clearance step underneath just the gear teeth that would come into direct contact with the printer bed. This was achieved by drawing 2 circles on the bottom face of the part to create a tire type area that covered the teeth and extruded into the part by 0.5mm, thus making a step that cleared the bed. I then printed the part using the 'Support' Feature in Cura and setting it to 'Touching Buildplate', which allows the actual teeth to be printed on top of the support to their correct shape and eliminating the spread factor. Next, I created a triangular wedge shape on the side elevation of the teeth starting at the inside corner of the step and widening to the top of the inside of the tooth by approximately 8 degrees (this is not a critical dimension - you can go up to 15 degrees but this will make the teeth narrower overall). I selected the triangle shape and did a sweep with it around the outside of the part, then removed that area. This now gives a smoother finish to the edges of the teeth. You can also do this on the top side of the part as well; this will improve the shape of the edge of the teeth if you're making a gear without a boss - there'll be no sharp edges. I hope this helps! All the files needed to show how to get these results are included, so give it a try - and it also works with simple clock gears!

With this file you will be able to print Better 3D Printed Gears with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Better 3D Printed Gears.