Belted extruder gears for Greg's Wade / L3K and many more

thingiverse

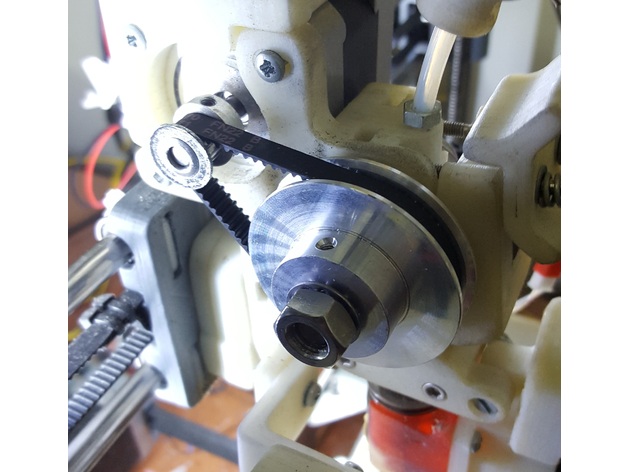

UPDATE (23-APR-2017): After months of successful use with the original pulleys, I had some aluminum pulleys left over and decided to try an aluminum standard GT2/60T pulley paired with a GT2/16T pulley. This swap included adding a design for a manual handler attached to the pulley using M3 screws. The torque is 1:3.75. It took 580 steps for 16 microstepping pololu and an 8mm hobbed bolt. The setup isn't cheap, but it's more durable and precise. I used high-torque S2M belts, which might explain why the extrusion feels smoother now. However, more data is needed before I update this info. Use caution with your pulley size and hobbed bolt length due to the 60T pulley's added height. I fixed it by attaching the handler with regular M3 screws and an M3 nut with anti-slip for extra security. It was a great idea to switch from ABS to black as after using plastic pulleys, they're no longer pretty and new. The result is a more discreet, better-looking build. UPDATE (27-OCT-2016): I posted sources as requested and acknowledge it's not the cleanest code. Sorry for any inconvenience. UPDATE (05-OCT-2015): New designs have been added to fit a variety of style gears. This setup works great with the L3K extruder using GT2 pulleys and a 6mm, 200mm, 100T belt. The "Crown" model looks amazing and can be used in place of Wade's typical 47/9T herringbone gears. I designed this based on existing awesome designs that inspired me. Both versions are available: 16T/90T pulley and 20T/86T pulley. Just swap out the old belt, add new ones, and you're good to go. This setup eliminated extruder backlash and retraction clicks while making it silent operation and more torque-friendly. It's a durable upgrade that's definitely worth the minimal cost (five bucks) for such impressive performance. Print slowly for better teeth definition and don't forget to recalibrate your firmware steps after setting up. Easy Installation: Simply swap out old pulleys in less than 30 minutes using a pair of needle-nose pliers to unthread the existing belt and tighten the new one. It's super easy! Belt Specs: - GT2 Pulley 16T, 6.5mm length, 5mm bore: 2 bucks - GT2 Belt Closed Loop, 100T, 200mm, 6mm tall: 1 buck Total Cost = 3 Bucks

With this file you will be able to print Belted extruder gears for Greg's Wade / L3K and many more with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Belted extruder gears for Greg's Wade / L3K and many more.