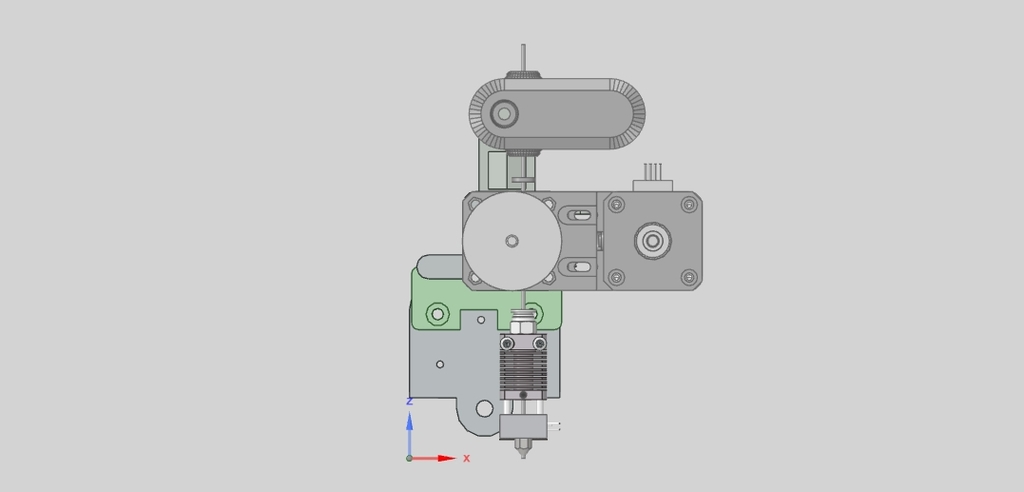

Belt Reduction Drive direct extruder stock Ender Eplate

thingiverse

This system solves several problems driving the cheap Bondtech style dual gear extruder: * Eliminates problems at high print speeds (above 120mm/s skipping with PLA). * Correct the mechanical alignment of the cheap dual gear extruder available everywhere. My design adds a great level of accuracy by using some simple belts, pullies and bearings to support longer moments within the extruder. Could probably use a "pancake" NEMA to reduce weight but didn't bother because I haven't had any problems with ringing or artifacts/skipped steps at any speed with 40mm NEMA motor. Steps/MM after install are around 420. NO affiliate links Needed to complete: * BondTech style dual gear extruder https://tinyurl.com/Dual-Extruder * This extruder is designed to be mounted to the Stock Ender 3 /3 Pro Hot end Plate * 1x 5mm x 80mm stainless screw https://tinyurl.com/5mm-screw-assortment * 2x 5mm Nylock nuts https://tinyurl.com/5mm-Nylock * 1x 20 tooth GT2 Timing Pully https://tinyurl.com/20T-GT2-Timing-Pully * 1x 60 tooth GT2 Timing Pully https://tinyurl.com/60T-GT2-Timing-Pulley * 1x 200mm GT2 timing Belt https://tinyurl.com/GT2-Belt-assortment * 1x 20mm x 3mm https://tinyurl.com/Flat-Head-assortment * 4x 18mm x 3mm Cap head screws https://tinyurl.com/Short-Cap-Head-assortment * 3x 40mm x 3mm Cap head screws https://tinyurl.com/Cap-Head-assortment * 1x extruder spring (Optional) https://tinyurl.com/Extruder-Spring * 4x 625zz bearings https://tinyurl.com/625zz-bearing

With this file you will be able to print Belt Reduction Drive direct extruder stock Ender Eplate with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Belt Reduction Drive direct extruder stock Ender Eplate.