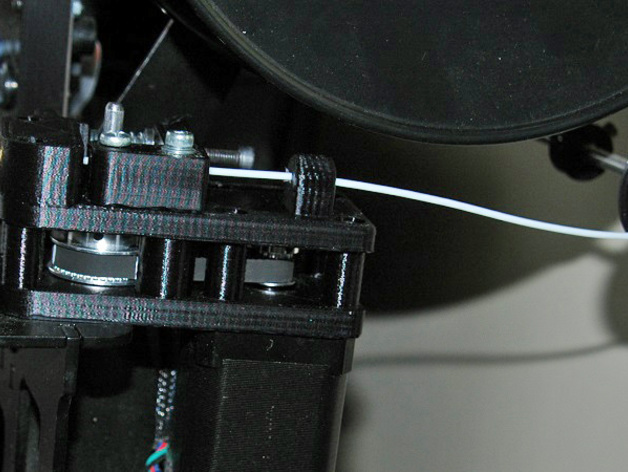

Belt driven Bowden extruder (1:2.5 reduction)

thingiverse

A belt driven Bowden extruder is designed for use with NEMA 17 motors and GT2 belts. The extruder attaches to the Prusa i3 top bracket, but it should fit any printer with a flat surface measuring 45 x 30mm that has screw holes drilled. This unit utilizes GT2 belts and pulleys for a 1:2.5 reduction ratio. It is designed specifically for 1.75mm filament, featuring a filament guide and shaped holes for easy filament loading. A white tyre paint pen was used to mark every 10 teeth on the belt, allowing for effortless monitoring of feed rates. On October 25th, 2015, an update (v1.04) replaced v1.03 files. The original upper bracket had not adequately deep locating pin holes; these have now been corrected. Other items I've designed for my printers include a GT2 belt clamp for the Prusa Y-axis, Arduino Mega and RAMPS v1.4 cases, a steel 10mm upgrade for the Prusa i3, steel Y-axis motor mounts, an X-carriage, E3D Chimera/Cyclops mount, dual E3D thermocouple amplifiers, a belt-driven Bowden extruder with 1:2.5 reduction, and various other enclosures and brackets. A Raspberry Pi case with a 40mm fan, as well as cooling ducts for Duet smart effectors and fans, is also included in this list. The Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License applies to this item. See the website provided for further details on licensing. Print Settings: Yes, rafts are recommended. Supports are also beneficial to use when printing with 0.2mm resolution and 50% infill. However, you can choose not to use them. Bill of Materials: There are three printed components involved in this project: The Upper frame The lower frame The arm Additionally, several items must be acquired from external suppliers: * A 75-tooth endless GT2 belt: Available for purchase at a wholesale rate on an online market platform. The specific supplier is detailed below. * A pair of 14mm OD bearings (5mm ID and 5mm thick) as well as a bearing with a 13mm OD and a 4mm ID (also 5mm thick): Also available from the mentioned online platform. The specific items needed can be found in their catalog. * A spring (with a 7.2mm ID, a 9.3mm OD, and 22mm length): This item is not standardly manufactured, but can be obtained through online wholesale marketplaces or local suppliers who may provide customization options. * Machine screws (M4 x 15mm and M4 x 45mm) as well as nuts of the same thread diameter: Standardly available at any hardware store in a wide range of quantities. * The Mk.7 extruder drive gear, a set of M3 x 30mm machine screws to secure the stepper motor), an M1/8 inch threaded Bowden connector and steel rod with a length of approximately 45mm for the idler shaft can all be sourced at wholesale on marketplaces like Aliexpress or purchased locally. To acquire all these necessary parts you might visit following suppliers: - A set of six GT2 belt timing belts with various specifications http://www.aliexpress.com/item/10pcs-3d-printer-belt-closed-loop-rubber-GT2-timing-belt-150-2GT-6-teeth-75-length/2038039243.html -16 tooth pulleys which serve to transmit motion from one pulley in the drive mechanism. The teeth of the two are timed, providing mechanical efficiency, to http://www.aliexpress.com/item/GT2-Pulley-16-Teeth-16teeth-Bore-5mm-tooth-Timing-Gear-Alumium-For-GT2-belt-Width-6mm/32301039517.html. - forty tooth pulleys used within similar timing mechanism. Also with 16teeth http://www.aliexpress.com/item/Wholesale-5pcs-lot-40-Teeth-GT2-Timing-Pulleys-Bore-5mm-For-Timing-Belt-Width-6mm-3D/32276844304.html. Supplier information can be used for reference only and might change due to product stock level and other supply chain management strategies that retailers have in place.

With this file you will be able to print Belt driven Bowden extruder (1:2.5 reduction) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Belt driven Bowden extruder (1:2.5 reduction).