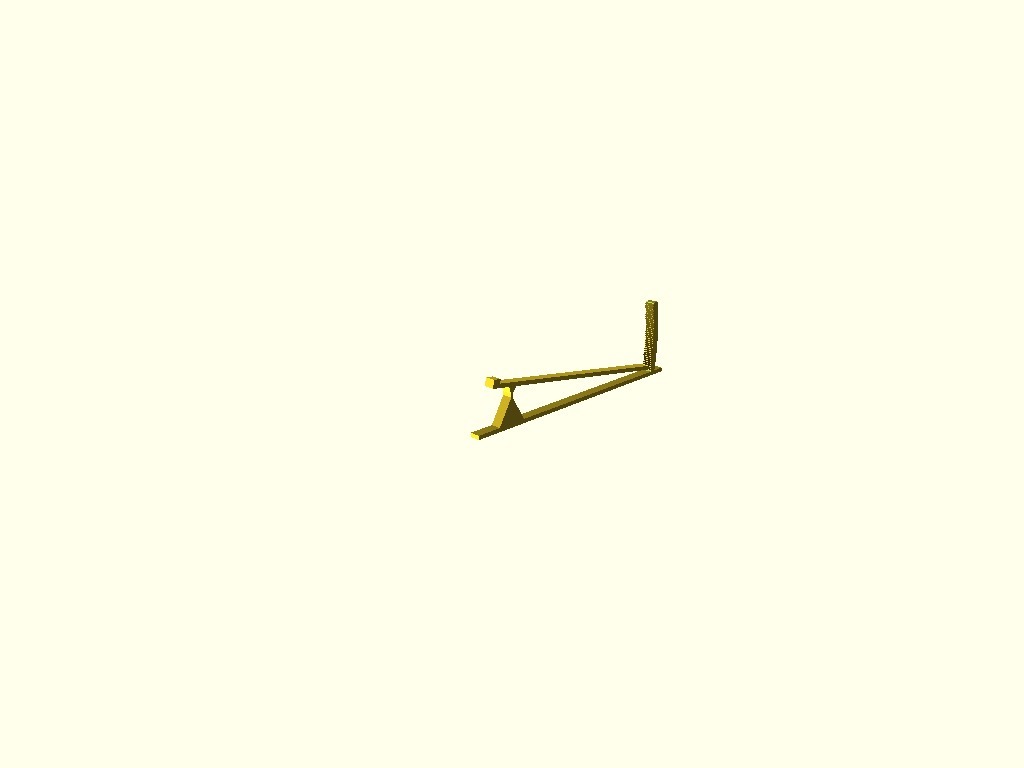

Bed leveling measurement tool.

thingiverse

For leveling the bed on a delta 3D printer, move the head to different positions near each of the three towers and adjust a screw to make the head come out at the same height above the bed in each corner. If you place this at the right spot near one tower, command the head to move to that tower at 35mm height, then come down to 23.2, which is the height with default settings. When all goes well, hit the middle of the platform on the short end of the see-saw and the indicator will move up. The middle of the scale is what you're aiming for. Adjust the "go to" height at the first tower to put the stick in the middle. Then move over to the next tower and adjust the endstop to make the stick end up in the middle there as well. Continue this way on the third tower, now your bed should be level. If necessary, repeat this in the middle of the bed to see if you've calibrated your rod lengths correctly. I use a little script called "X" to go to the X tower, optionally at a specific height. The script is: "#!/bin/sh", followed by an if statement checking the number of arguments. If there's one or more, set Z to that argument; otherwise, set it to 2. Then echo G0 X-95 Y-55 Z$Z F6000 > /dev/ttyUSB0. If you intend to use this script for leveling, I recommend setting the default height to 35mm earlier recommended. Next, use a script called "lower" to do: "#!/bin/sh", followed by an echo statement sending G0 Z$1 to /dev/ttyUSB0. This way, you can say "lower 23.2" to go to that height. I used these scripts on my Octopi control computer for the 3D printer. I printed this in PETG with a bend_len much shorter than usual, causing the device not to bend back fully after being depressed. You might need an even longer bend_len if you print in PLA. For printing, rotate it by 90 degrees and use no support; instead, recommend a significant brim because otherwise the long bars will pull loose from the bed (maybe not necessary for PLA). My printer is unable to resolve the tickmarks fully, but you can easily see them even if they don't look like what was designed. When customizing: ratio is the "amplification ratio" between the head and the indicator. Adjust bend_len for the bendy-ness of your material. Ideally, the bend_thickness should be one single extrusion width. But I couldn't get my slicer to connect that piece of my model with the outside of the rest of the model, so check the layers view of your slicer before printing! I printed it at 10mm width and thought 5mm would be enough to hit the platform. However, if you print it and it becomes too top-heavy and topples over easily, let me know and I'll put the default back to 10mm. We decided to A) print it again and B) use it again. It was now a snap to level the bed: just read the indicator, turn the screw, and try again.

With this file you will be able to print Bed leveling measurement tool. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Bed leveling measurement tool. .