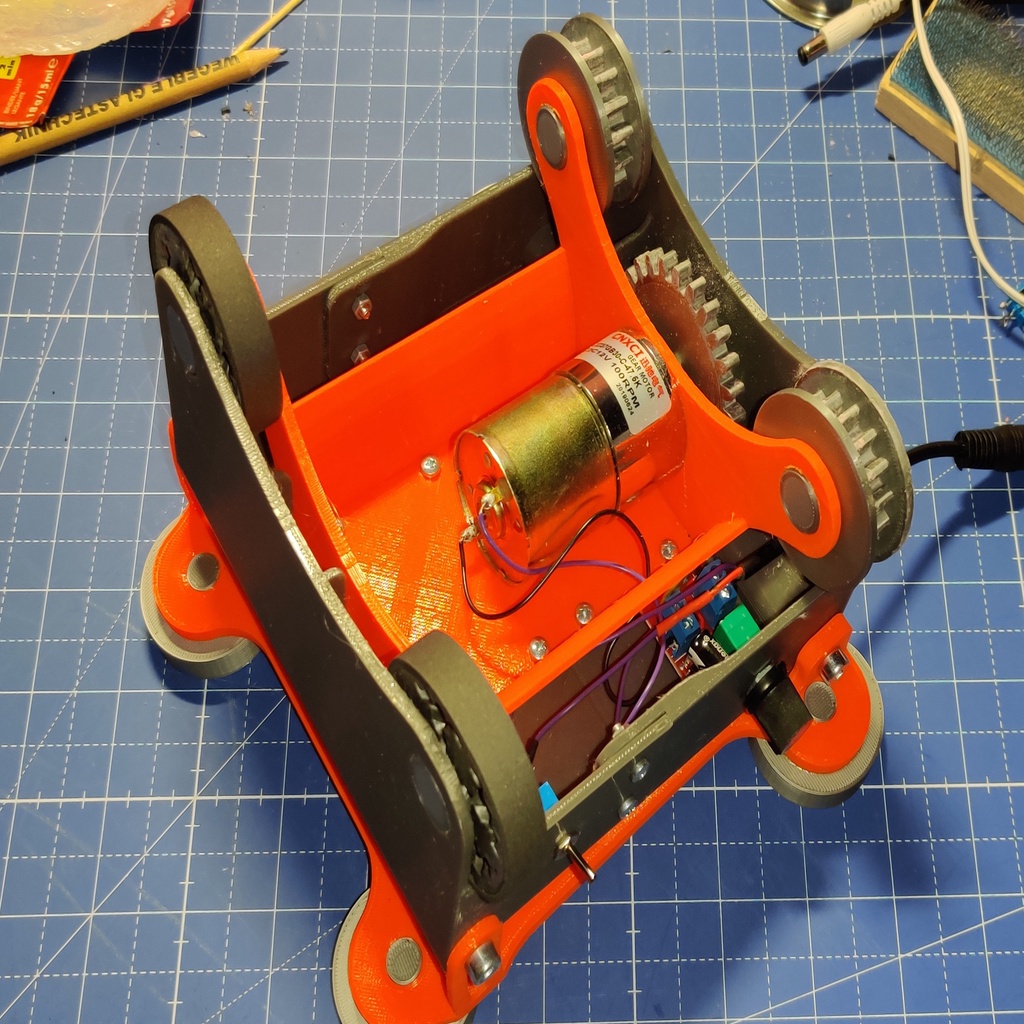

Bearings for Polisher Gear and Support Wheels

thingiverse

UPDATE: Hello again, I finally had the chance to update my files for the new 170mm version of the polisher. Here's what changed: The only parts that needed an update are the support gear and the support wheel. The new wheel is actually smaller, shrinking from 44mm to 40mm in diameter, but I decided to update it anyway. You can still use your old support wheels; they just tilt the drum a bit higher. The bolts I designed for the original polisher fit perfectly with the new ones. The instructions remain largely the same, except you'll need to print one of each gear half since their teeth are oriented differently from the originals. I've printed the parts to test the assembly, but I haven't updated my own polisher yet. So, in theory, everything should work out. If there's a problem, let me know. Hello everyone, I'm a huge fan of the "reittec Polisher" designed by reitter_m. But during use, I encountered an issue where the support wheel broke due to excessive friction with the bearing. You know how plastic behaves under heat - even PETG. So, I thought, why not add bearings to the support gears and wheels? And that's exactly what I did. Replacing the support wheel was relatively easy since it's just a cylinder. Thanks to emmett's "Gear Bearing" and customizer, I could easily create a printable bearing to replace the original one. For the support gear, however, this wasn't possible, so I used a common 608 bearing instead. After a few hours of testing in Fusion 360, I designed bolts and caps that would hold the bearings in place. I printed all the parts on my Prusa MK3S with 0.15mm clearance and tolerances. If your printer has issues with this level of precision, some sanding might be necessary. The bolts and caps I designed are meant to fit into the frame without the original bearings, so make sure to remove them first. I hope you find this helpful and enjoy! Instructions: To replace the Support Gears, you'll need: * 4x Support Gear Half * 2x Bolt 1 * 2x Bolt 2 And to replace the Support Wheels, you'll need: * 2x Bearing Support Wheel * 2x Support Bolt 1 * 2x Support Bolt 2 Optional materials include plastic glue, superglue or epoxy, and EVA foam (0.2mm). For the support wheels, even with a 0.15mm tolerance, I had to use some force to get them spinning smoothly. A 6mm allen key should help if it gets stuck. If you're having trouble, try increasing the tolerance in the customizer to 0.2mm or more. If you feel like it, give the top surface of the printed bearing a slight sanding for added smoothness. I also cut some EVA foam strips and glued them onto the surface of the bearing for better contact with the glass. Once again, push the bolt through the bearing and put the cap on. It should be a tight press fit. If you feel like adding some glue between the bolt and the bearing or the cap, do so, but be careful not to get any into the gears of the bearing. Repeat for the second Support Wheel, test, and replace it on the polisher. Settings for the customizer: * D = 44 * T = 9 * tol = 0.15 (default) * number_of_planets = 5 * number_of_teeth_on_planets = 7 * approximate_number_of_teeth_on_sun = 9 * P = 50 * nTwist = 1 * w = 6.5

With this file you will be able to print Bearings for Polisher Gear and Support Wheels with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Bearings for Polisher Gear and Support Wheels.