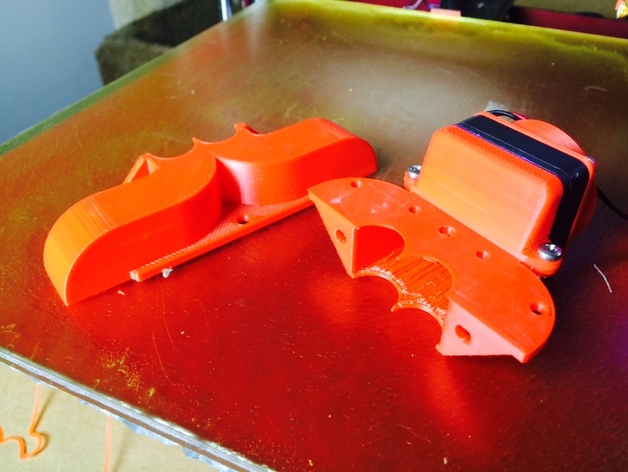

Barrel cooling duct for MendelMax 2 & JD Duallie Belt Driven Extruder

thingiverse

I designed this part to prevent heat creep issues in J-Head barrels during dual extrusion, a problem that doesn't occur with single extrusion. It's always best to cool the barrel anyway, so I incorporated features to tackle this challenge. Additionally, I wanted to reduce turbulence in intake and exhaust that could cool the part unnecessarily. This design focuses on J-Head hot ends, but can be adapted for hot ends with 16mm diameter barrels. My intention is for use with ABS and similar materials where cooling isn't desired. However, PLA prints will require an extra fan to cool the part after laying it down. Instructions: The intended line width is 0.5mm, so a 0.4mm or smaller nozzle is recommended. To assemble this design, you may need to tap the MM2 carriage, which I used M4, M5, and M6 taps for different holes. Additionally, various sizes of M3, M4, M5, and M6 hardware will be necessary. Unfortunately, there's an assortment of hardware required due to the unique characteristics of the mount plate in question. To attach everything together, use pan head screws with Phillips drive, though other options may also work. You'll specifically need: - 2x M6 x 8mm (or longer) for rear side mounts - 1x M5 x 8 for the center rear mount - 4x M4 x 8-12mm long pan head screws for front side mounts and joining the sections together - 2x M3 x 6-10mm to secure the top fan shroud - 4x M3 x 18mm screws for attaching the fan and intake

With this file you will be able to print Barrel cooling duct for MendelMax 2 & JD Duallie Belt Driven Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Barrel cooling duct for MendelMax 2 & JD Duallie Belt Driven Extruder.