B'Struder: Universal Bowden 1.75mm Extruder

thingiverse

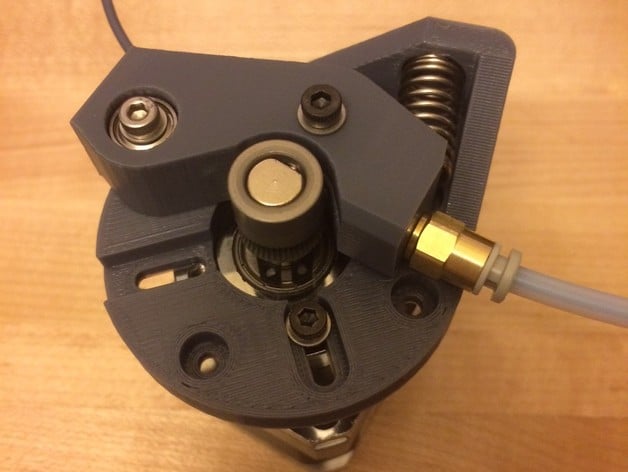

The Bowden extruder known as the B'Struder represents an entirely new design. It's engineered to accommodate all standard stepper motors and most common pinch gears, providing users with considerable flexibility in choosing their hardware. Various tube connection options are available, enabling individuals to pick the best components for their specific requirements. All you need is a handful of M3 screws and nuts, a suitable ~3/8" or ~10mm spring, and three 623 bearings. The unique feature of this extruder design lies in its filament path running entirely through the spring idler arm. This accomplishes two notable benefits: 1) Filament alignment proves to be quite tolerant of varying pinch gear diameters. 2) It makes the tension on the Bowden tube slightly assist the grip of the pinch gear. The precise geometry for several key components, such as the hinge, idler bearing, output fitting, and pinch gear contact point, is crucial. Given that this is a new design, feedback from users would be appreciated but thus far, it's working perfectly well in my Delta with very aggressive retraction settings without any complications. [UPDATE 11-13-15] Consistent excellence in performance has been achieved. With over several hours of running time on each device, two of them have proven themselves reliable and functional. Minor modifications can be considered to further enhance the design: 1) Widen the filament inlet slightly. 2) Expand fitting options (e.g., include an E3D pushfit insert or M4 tube connection to the drive gear for flexibles). For more choices, see the "remixes." Instructions Printing requires: The arm must be printed at 0.1mm resolution with >50% infill and sufficient print cooling. PLA works fine. Print upright without supports since STLs are oriented that way. If necessary, use a hobby knife or drill to clean up bearing pockets or the filament path depending on your printer's design. Assembly consists of: * Sticking an M3 nut into the nut pocket * Inserting two 623 bearings into the hinge pocket for a snug fit * Screwing a 12-14mm M3 screw into the nut to secure the bearing Then print the plate using any settings as long as they result in strong parts. Supports aren't necessary; I recommend ABS for motor overheating, but that may pose some risks. Alignment is crucial: For NEMA 17 motors, match the hinge pivot hole with the motor bolt pattern. For smaller or geared motors, align slots with motor bolts and remove supports from the hinge pivot to reveal the M3 nut pocket. Securely attach the plate to the motor. Attach the arm hinge to the plate, keeping it snug but avoiding bearing binding. Applying a dab of thread locker is a good idea for safety. Insert pinch gear onto the motor shaft and ensure alignment with the idler. Install spring and make sure everything works seamlessly together. Common extruder steppers: It's compatible with pretty much any extruder stepper featuring a centered shaft and 22mm "pilot." This should cover most NEMA 17, geared or ungeared options; it should also work with most NEMA 14s. The following specific options have been successfully tested: TriDPrinting.com 8mm bore hardened pinch gear Makerbot Mk7 gear Random eBay mk8 gear QU-BD Raptor

With this file you will be able to print B'Struder: Universal Bowden 1.75mm Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on B'Struder: Universal Bowden 1.75mm Extruder.