AutoStryfe mod kit

thingiverse

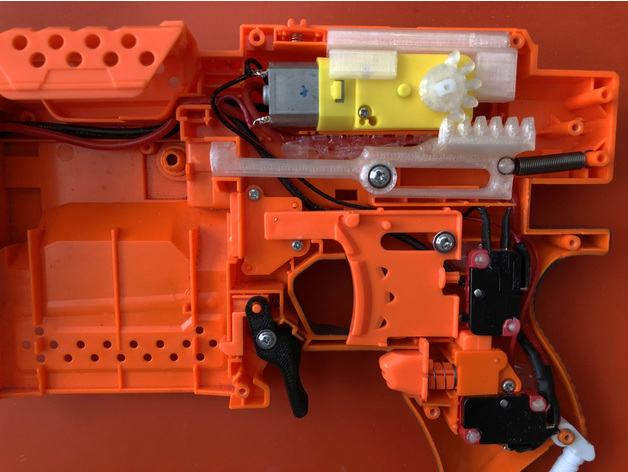

Human: AutoStryfe V2 mod kit for the Nerf Stryfe. Requires 130 motor gearbox available on Ebay, Amazon, etc. through various vendors (search: Arduino rover). Overview: https://www.youtube.com/watch?v=C2jc6e_qjzA&t=230s. Markus1406 has modeled and uploaded an excellent printable pusher arm for this kit linked below (this part still works with the updated kit): http://www.thingiverse.com/thing:2279902. GearBoxBrace010 file has machine screw hole pre-tapped. Alternate orientation GearBoxBraceScrewsUp is for mounting the gear box screw side up. Closer inspection of failed gear boxes revealed that the side of the gear box without screws has a friction fit post output shaft that is easily stripped, rendering the shaft useless. On the upside, the screw side up output shaft is press fit into the gears, making this side generally harder to strip. If both output shafts were left intact, it is possible to use either output shaft if or when one fails. Just use the appropriate gear box mount and remember to re-solder the pusher motor polarities (flipping the gear box over will make it rotate counter clockwise). Minor update to the spur gear. File cleaned up with simpler geometry. Two versions available now: original 8mm for maximum surface area/looser tolerances. 5mm is recommended if the spur gear is rubbing against the inside of the opposite Stryfe shell half (check the inside of the shell for rub marks or for the telltale orange plastic on the gear teeth). Less friction = faster cyclic rate and less strain on the motor/gear box. Pusher arm spacer is now 11mm in diameter to allow for greater tolerances in prints. This piece should spin/move freely around the mounting screw to reduce friction as the pusher arm is cycling. Added: AutoStryfePusher. Replaces the separate gear rack/modified stock pusher arm solution. Maintains the 1:1 gear tooth matching. Extends the pusher head slightly over stock to improve feed reliability. Orient the pusher arm flat on the print bed when slicing. Half of the pusher face was omitted to facilitate this. This will result in a smooth, flat surface optimal for the higher friction of faster feed rate motor set ups. Return spring peg was designed to print without supports (it was difficult to remove support material inside the spring well), and holds up when printed with with 1.6mm walls (4 perimeters on .4mm nozzle) rather than increasing the infill. GearBoxAxelCap is an optional piece added for additional safety. When mounting the gear box screw side up and removing the opposite output shaft, it is possible for the exposed spinning output shaft to come into contact with a LiPo battery or wiring inside the battery tray depending upon how the installation was done by the user. It should go without saying that a spinning shaft with teeth could potentially abrade wire insulation or battery insulation, however low those odds may be. Better safe than on fire. Print Settings: Printer Brand: Creality Printer: CR-10S Rafts: No Supports: Yes Resolution: .2 Infill: 20%

With this file you will be able to print AutoStryfe mod kit with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on AutoStryfe mod kit.