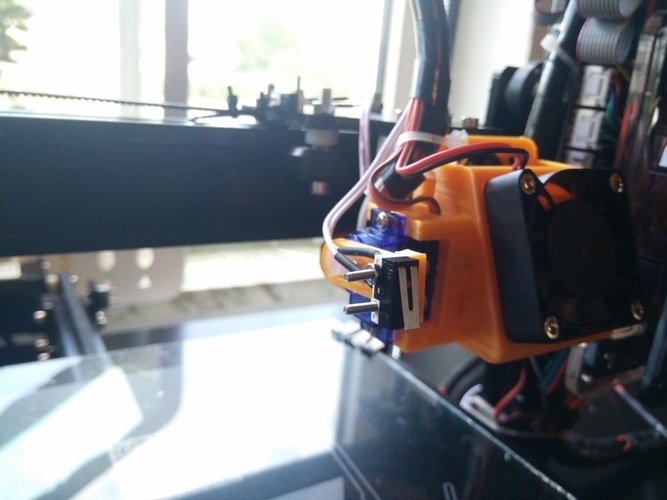

Auto Bed Leveling with SG90 Servo for Tevo Tarantula

pinshape

I made this design based on the fanduct by Elzariant.\nI just added a mount for the SG90 servo to use it for auto bed leveling.\nI also added a single version of the SG90 Mount, so you can glue / solvent weld the part to your existing fanduct / hotend and my configuration.h file for reference.\nhttps://www.youtube.com/watch?v=0fFdSMcWNZM&feature=youtu.be\nWhat do you need?\n\nSG90 servo (and the accessoires it came with)\nthe printed parts (arm + servo mount)\na ready to use configuration of Marlin or your prefered firmware\nPrint SettingsPrinter: Tevo TarantulaRafts: NoSupports: YesResolution: 0.2Infill: 25 %, 3 ShellsNotes: I used manual support on the mount for the SG90 - don't use support anywhere else!\nPost-PrintingGet the MKS Base to use the Servo (Marlin 1.1.0)\nThe MKS Base does not have any exposed pins that are compatible with servos (PWM). So you have to use the x-max pin-out, which is defined as digital pin 2.\nTo do so, we have to change the assigned pins in the firmware. Open up Marlin and go to the 'pins_RAMPS_14.h' tab (pins_MKS-13.h redirects you to pins_RAMPS_14_EFB.h redirects you to pins_RAMPS_14.h).\nSearch for: '#define X_MAX_PIN 2'\nand change it to: '#define X_MAX_PIN -1'\nthen search for: '#define SERVO0_PIN 11'\nand change it to: '#define SERVO0_PIN 2'\nGo to configuration.h and uncomment the following:\n'#define NUM_SERVOS 3\n\n(Note: I had to change the line to: '#define NUM_SERVOS 1' otherwise my x-Axis had problems moving - don't know why, just for your information)\nAlso you have to uncomment (in configuration.h): '#define AUTO_BED_LEVELING_FEATURE'\nAnd define the 'spots' where the probe should level (I use this values with the large bed):\n'#define LEFT_PROBE_BED_POSITION 30\n'#define RIGHT_PROBE_BED_POSITION 130\n'#define FRONT_PROBE_BED_POSITION 30\n'#define BACK_PROBE_BED_POSITION 200'\nDefine the probes offset from nozzle (especially the Z_PROBE_OFFSET_FROM_EXTRUDER is important and should be accurate to about 0.1mm, I ended up using -9.1, your value may differ):\n'#define X_PROBE_OFFSET_FROM_EXTRUDER -55\n'#define Y_PROBE_OFFSET_FROM_EXTRUDER -35' // ~0 for V2\n'#define Z_PROBE_OFFSET_FROM_EXTRUDER -8'\nDefine the angles which the servo has to 'hold' for probing and parking (the last two numerics, the values depend on how you mount the servo arm - use M280-command to find the right values):\n'#define Z_ENDSTOP_SERVO_NR 0\n'#define SERVO_ENDSTOP_ANGLES {{80,180}}'\nAlso change: '#define Z_RAISE_BEFORE_PROBING 5' to '#define Z_RAISE_BEFORE_PROBING 20'\nAt last, make sure the following is uncommented, or the servo will 'wobble' around while printing:\n'#define DEACTIVATE_SERVOS_AFTER_MOVE'\nUpload your new firmware. Plug in the servo. Be careful, you have to change the servos wires (the plug is s/+/-, the pins on the board are s/-/+).\nNow you can use the M280-command to test the servo, e.g. M280 P0 S20 (sets servo 0 to position 20). With this command you can also find the correct values for the servo angles.\nAfter homing your X and Y-Axis (G28 X0 Y0) and running the auto bed leveling process you can use G1 Z0 to lower the nozzle onto the bed. If the Nozzle is too far away from your bed, lower the value, if the nozzle crashes into your bed, raise the value.\nAt last, change the start script in your slicer. Replace: G28 //home all axis with G28 X0 Y0 //home X and Y-axis\nG29 //auto level build plate

With this file you will be able to print Auto Bed Leveling with SG90 Servo for Tevo Tarantula with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Auto Bed Leveling with SG90 Servo for Tevo Tarantula.