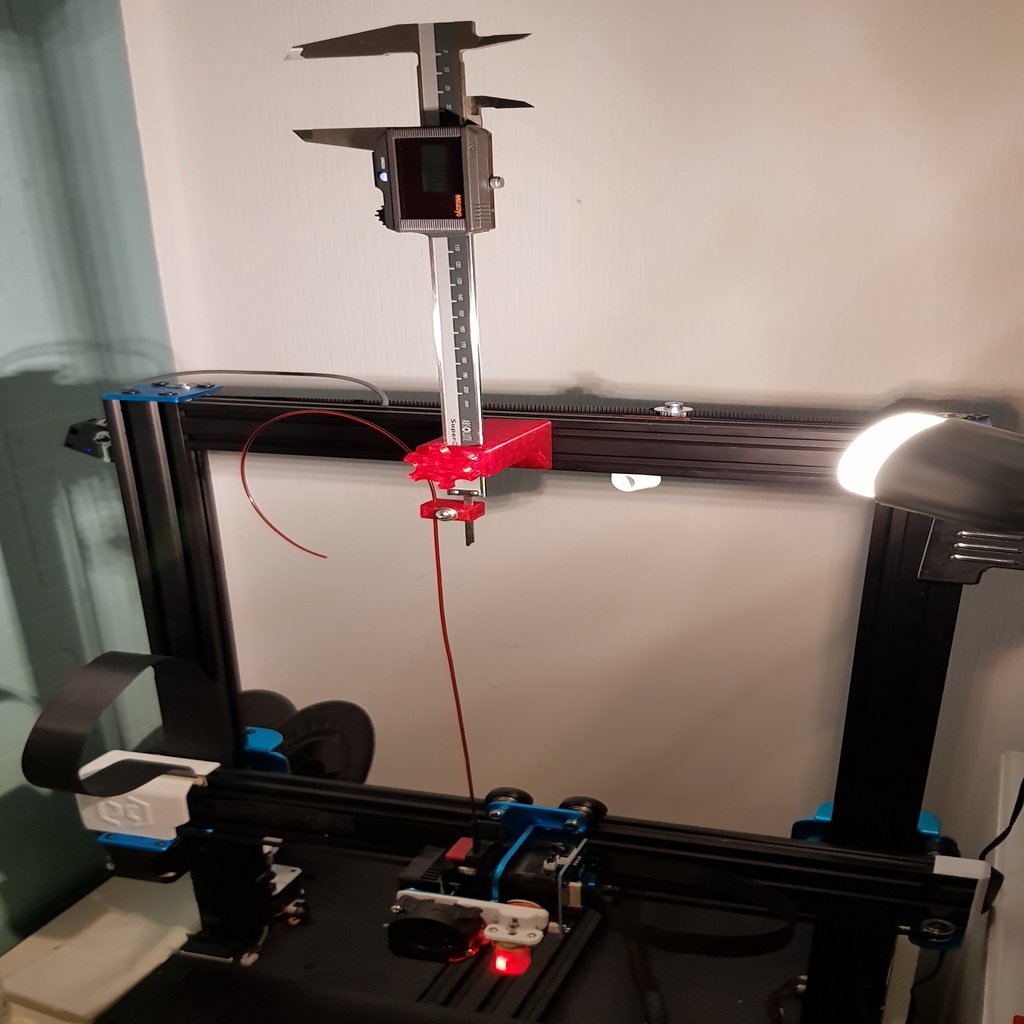

Artillery Sidewinder X1 - Nut 6 Extruder Step Calibration Tool V3

thingiverse

Important: To Print Threads, Your Printer Must Be Calibrated Really Well. Accept the challenge! It's Worth the Effort, After That, Your Printer Works Dimensionally Accurate. Just in case one might think it doesn't work... taken from my ruler stop. My Calibration Sequence is Crucial: - Make Sure Your Printer Stands on a Level Surface - Ensure the Ground or Subsurface Does Not Shake While Printing - Align Your Printer Exactly and Build It Properly - PID Tuning: Follow This Link for More Information http://marlinfw.org/docs/gcode/M303.html - Optimize Your Bed Levelling, at Least Get a First Layer Without an Elephant Foot - Calibrate Extruder Steps and Correct in Firmware or Start GCode - Measure Average Filament Diameter (Edit in Slicer) - Calibrate Extrusion Multiplier (Edit in Slicer) https://www.thingiverse.com/thing:1796601 - Calibrate X/Y Steps and Correct in Firmware or Start GCode https://www.thingiverse.com/thing:2484766 http://marlinfw.org/docs/gcode/M092.html - Calibrate Z Steps and Correct in Firmware or Start GCode https://www.thingiverse.com/thing:2484766 http://marlinfw.org/docs/gcode/M092.html - Print a Temp Tower to Find Suitable Temperature for Your Filament and Edit Your Slicer https://www.thingiverse.com/thing:2493504 The Second Thing is... The Caliper Must Move Smoothly and Easily... Good Time to Clean It Up and Give it a Soft Lube with Tool Oil. Edit 2: Fiddling the Screw into the Clamp Was a Hassle, so I Made the Clamp Magnetic. I Used 12 Neodymium Magnets 3mm x 3mm and 2 Magnets 10mm x 2mm. The Magnetic Clamp is Symmetrically Printed Twice. Edit: Added 16mm and 18mm Versions Depending on Your Caliper, a Rounded Knob and a Bracket with Blind Hole for M4 Nut. Tool to Calibrate E-Steps Properly with a Caliper. Mainly Made for My Artillery Sidewinder X1, But Should Fit Every 20XX V-Slot Frame with "Nut 6". Made for Max. 100mm Extrusion. Filament Between Extruder and Caliper Must Have Tension Before You Begin. Ideal is to Clamp It Together and Extrude Some MM for Tensioning. Read E-Steps with M92 Send: M92 Recv: echo: M92 X80.29 Y80.37 Z399.64 E588.00 Recv: ok Connect Caliper, Heat Up the Extruder, Extrude for Example 100mm of Filament. Calculate New E-Steps. New Steps = (Demanded Length / Real Length) * Actual Steps. Write with M92 EXXX.XX. Save with M500. You Will Need an M4 Brass Insert, Soldering Iron for the Insert and an M4x15 Bolt for the Clamp That Connects Filament and Caliper. You Can Use It Without Changing Filament. In My Case, the Spool Was at Its End... https://youtu.be/nFTs8omnDNM

With this file you will be able to print Artillery Sidewinder X1 - Nut 6 Extruder Step Calibration Tool V3 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Artillery Sidewinder X1 - Nut 6 Extruder Step Calibration Tool V3.