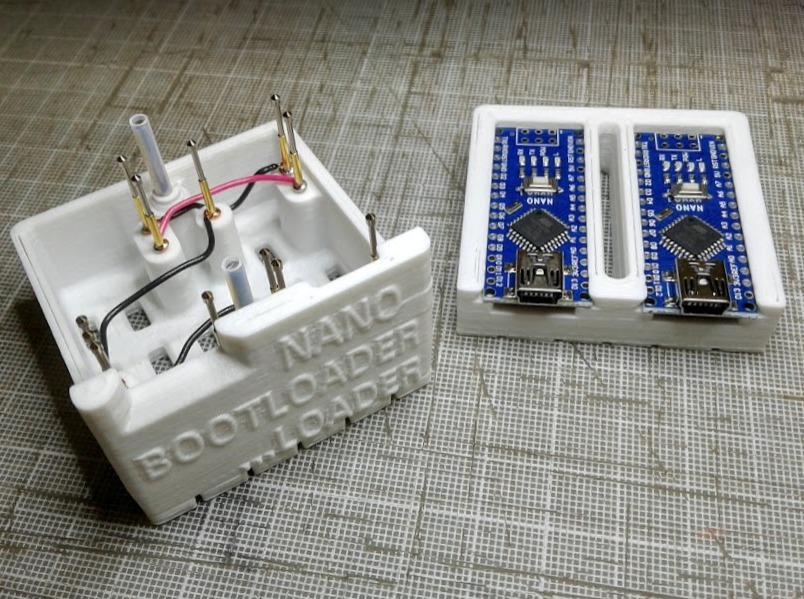

Arduino Nano Bootloader ...loader (Arduino as ISP programmer)

thingiverse

If you buy Arduino Nanos from China and need to use them pin-less, this may be a great project for you. I'm putting these Nanos into products and find hooking them up very time-consuming and risky. This little tool is based on the Arduino IDE to program a master NANO as an ISP (Arduino as ISP). All pins are connected according to the included IDE example sketch "11.Arduino ISP". Power, ground, D11, D12, and D13 are one for one. The source Nano uses D10 connected to the target Nano's reset. The contacts I'm using are P100-E2 Dia 1.36mm (eBay). I'm also using a solid 22awg wire to connect them, providing some rigidity so that the pins side by side don't accidentally short. The wire manages the depth of the pins fitting into the case. I put the wire at the crimp of the contact housing, biased slightly closer to the contacts. You'll need to drill out the holes when printing these on most printers. The head of the contacts freely fits through the upper carriage. The contact bodies are a close-fit to the base. Trying to get them press-fit proved destructive to several contacts, so I just drilled them out to 1.5mm in ABS. Maybe smaller for PLA. You want them to remain as straight and rigid as possible. I will probably glue them down over time, but this works fine as-is. The guide posts are bicycle spokes with some Teflon tubing to make up the gap. I opted not to clamp the two pieces, as the operation only takes seconds. However, you can use longer threaded posts and a thumb-nut if you want to be able to set it aside while installing programs to the target Nano and other operations. One word about the print files: I used a 3D Systems CubePro to print these. The CubePro is fanatically accurate and often under-sizes features, so nominal prints fit together well. I've put in all the caveats in the print to make sure this is pretty darn close right out of the box. If you find your Nano's fitting tight in the carrier, widen the slot a little. I always clean the edges of my Nano's first. In my build, the Nano's fit quite loose. You can also dump the sidewalk (border on the base). I put it there because the slicer's sidewalk wanted to fill the gaps. Oh, the gaps are there to minimize warping. You need a good strong hold on the build plate for these if you print with ABS. However, PLA should be simpler. I ran both parts as "Solid". If you need a simple tweak on the model, please post your request in comments and I can see what I can do to help. I can tell you that I just reduced a 30-minute job into mere minutes. Edit: 04/25/2019 I've added a version that includes all pins for the Nano. You're on your own for how to configure it. Both models are in MM.

With this file you will be able to print Arduino Nano Bootloader ...loader (Arduino as ISP programmer) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Arduino Nano Bootloader ...loader (Arduino as ISP programmer).