Anycubic Chiron 3D Printer Enclosure - legs and corners

thingiverse

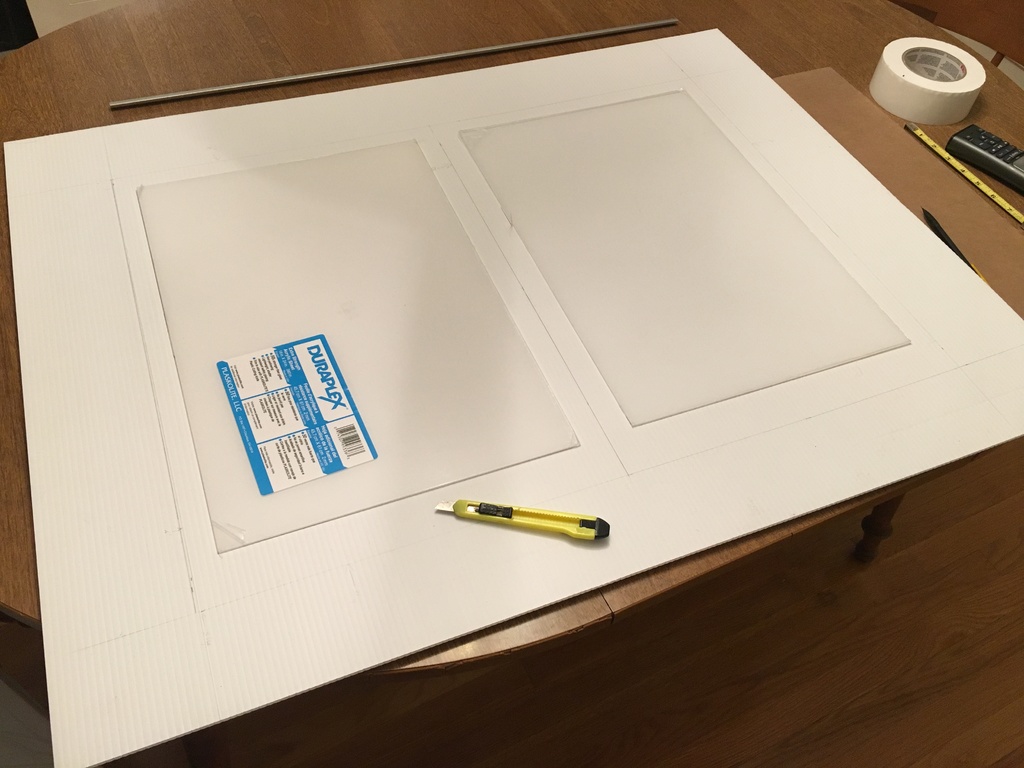

Goals: 1. Design an enclosure that maintains a stable temperature around the 3D printing area and encloses the filament spool. 2. The enclosure must be suitable for use with filament types like ABS, which require stable temperatures. 3. Keep the total cost under $100 while ensuring quality is not compromised. 4. Provide easy access through the front and sides by installing large doors. 5. Ensure ample viewing from the front and sides using clear plexi-glass. 6. Construction must be relatively easy to execute using common tools, such as hand tools, without requiring power tools. 7. The enclosure should not enclose the 3D printer's power supply; instead, raise it above the power supply for adequate ventilation. 8. Use the 3D printer to create custom corners that hold the enclosure together. 9. Seal the seams between panels using White Duct Tape. Costs: 1. Two White Twinwall 4mm thick 72"x36" plastic sheets from Home Depot cost $18 each, totaling $36. 2. Two Clear Plexi-glass 2mm thick 24"x18" sheets from Lowes can be cut into four pieces (two for front door windows and two for side door windows) for $13 each, totaling $26. 3. One roll of 2" wide White Duct Tape costs $7. Miscellaneous self-screws are used as needed. Total cost: $69 How To: 1. Cut one twinwall sheet into two 36"x28" panels (sides), one 36"x16" panel (part of the back) using a razor knife. 2. Cut another twinwall sheet into one 36"x36" top panel, one front 36"x28" panel, and one 36"x8" part of the back. 3. Cut a piece of cardboard to 36"x4" for use as part of the back. 4. Tape the back parts together to form one 36"x28" back panel; cover the cardboard with White Duct Tape. 5. Cut two 18"x12" holes in the front for plexi-glass windows in the front doors. 6. Cut one 18"x12" hole in each side for plexi-glass windows in the side doors. 7. Attach the plexi-glass to the door cut-outs using White Duct Tape with a half-inch overlap. 8. Cut all the way through on the three free sides of the doors. 9. On the hinge side of the doors, only cut halfway through on the inside so that the doors will swing outward; reinforce the outside hinge side with White Duct Tape. 10. 3D print the leg corners, top corners, and caps as well as door knobs using a 0.8mm nozzle. 11. Assemble the enclosure into its corners. 12. Use White Duct Tape to seal the seams between the front, top, back, and side panels. Links: 1. Twinwall plastic sheets can be found at Home Depot: https://www.homedepot.com/p/72-in-x-36-in-x-5-32-in-Twinwall-Plastic-Sheet-COR-3672/202771364 2. Clear plexi-glass sheets are available at Lowes: https://www.lowes.com/pd/DURAPLEX-0-08-in-x-18-in-x-24-in-Clear-Acrylic-Sheet/3143519 3. White Duct Tape can be purchased at Lowes: https://www.lowes.com/pd/3M-Tough-1-88-in-x-55-White-Duct-Tape/1000104181 4. Leg corner STL files are available in this posting. 5. Top corner STL files are available in this posting. 6. Top cap STL files are available in this posting. 7. Knob STL file can be found on Thingiverse: https://www.thingiverse.com/thing:356075 8. Latch STL file is available on Thingiverse: https://www.thingiverse.com/thing:655519

With this file you will be able to print Anycubic Chiron 3D Printer Enclosure - legs and corners with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Anycubic Chiron 3D Printer Enclosure - legs and corners.