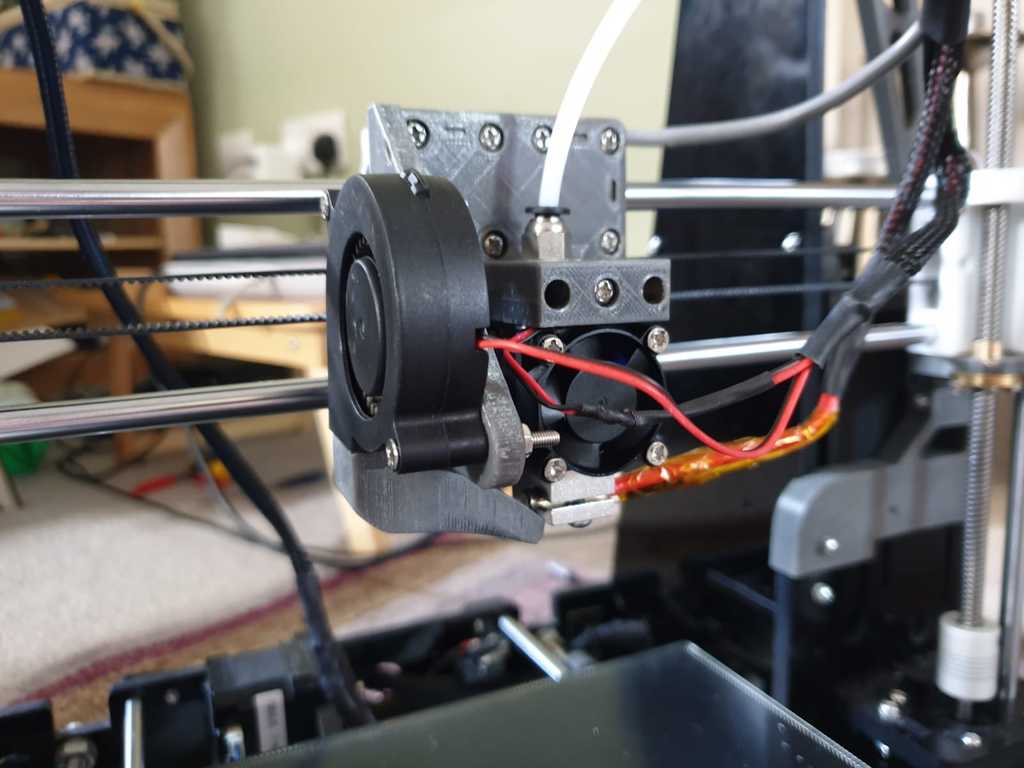

Anet A8 E3D V6 Bowden Mount (With Nut Inserts)

thingiverse

This is a revised version of TNS's E3D V6 Mount for the Anet A8, with key modifications to ensure a secure and hassle-free mounting experience. Unlike the original design, which relies on threading directly into plastic, this remix uses M3 square nuts inserted into the square holes of the part, eliminating the risk of stripping the threads when removing the carriage for maintenance or blockage clearance. I also widened the circular cutout in the mounting part of the carriage and introduced an optional grub screw to secure the hot-end firmly in place. This feature utilizes an M3 square nut insert and can be beneficial for printers with varying tolerances, particularly clones that may have a slightly loose hot-end due to dimensional inconsistencies. The E3D V6 clone I'm using serves as the basis for this remix, but it should work seamlessly with original hot-ends as well. To confirm compatibility, refer to TNS's instructions on measuring the hot-end, ensuring that this carriage will meet your printer's specifications; my clone measured 63mm, which is the file I based this remix on. Installation instructions: 1) Insert six M3 hex nuts into the corresponding holes on the face of the carriage for a secure mount with a belt holder of your choice. You may need to heat up the hex nut and press it into the hole for a snug fit. Install the carriage onto the x-axis bearing holders and original screws. 2) Insert two M3 square nuts into the holder of the main carriage, making sure the hole of the nut aligns with the hole in the part. 3) Install an M3 nut into the smaller mount part, which is for the grub screw. Use an 18mm M3 bolt as the grub screw and insert it, ensuring it's flush with the semi-circular face of the part. Insert two 18mm M3 bolts into the holes on either side of the central grub screw (all screws should be loose in the plastic). 4) Insert the hot-end into the mount, aligning the two parts, and thread the two screws of the smaller part into the main carriage, making sure the square bolts are aligned. 5) Tighten the grub screw until the hot-end is stiff and doesn't rotate. This may mark the hot-end, but this area will be hidden anyway. 6) Attach your desired belt holder to the rear using six 22mm M3 bolts. You're done! Use the zip tie holes to tidy up your wires. Parts required: - Six M3 hex nuts - Six M3 Bolts of at least 22mm length (can be longer), used for the belt holder - Three M3 Square nuts - Three M3 18mm bolts Other 3D prints used in this project include: - Mistral 2.1: https://www.thingiverse.com/thing:2121279 - Bed Level Sensor Mount: https://www.thingiverse.com/thing:2105275 - Belt Holder: https://www.thingiverse.com/thing:2427494

With this file you will be able to print Anet A8 E3D V6 Bowden Mount (With Nut Inserts) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Anet A8 E3D V6 Bowden Mount (With Nut Inserts).