Anet A8 Dual Bowden Conversion

thingiverse

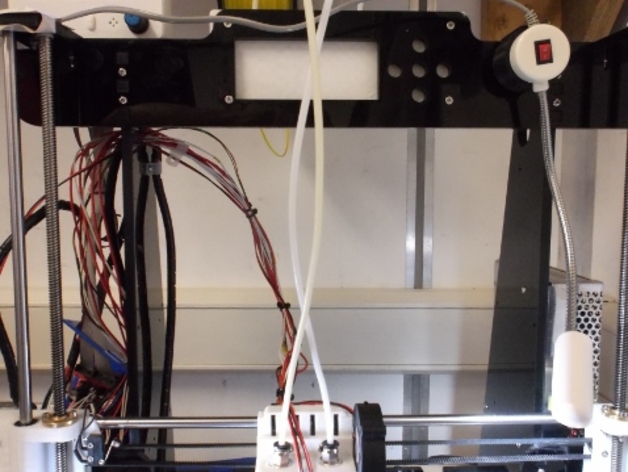

I've designed a printer upgrade to boost accuracy and enable dual-color printing. By minimizing the moving mass on the print head, I hope to achieve faster printing speeds. The hot ends are positioned as close together as possible to preserve build space while allowing both nozzles access to the entire build plate. The auto level servo mount was designed to avoid taking up valuable space or interfering with the printer's sides. It's crucial to route heating and thermistor wires carefully to prevent them from hitting the frame during X-axis homing or when the hot ends are on the far side of the build plate. This design, like many others, directs hot end cooling air out the sides of the mount, keeping it away from the build plate. Most small servos have a significant amount of slop in their gear trains. The servo arm designs I've seen often place the switch button off-center with respect to the servo shaft. When the switch hits the build plate, the force causes the arm to rotate slightly, which changes the actual reading each time it hits the plate. By keeping the switch button aligned with the servo shaft, forces are applied more directly to the bearing surfaces and less to the gear train. This results in less deflection/movement during auto-level operations. I've included two servo arms; one has holes designed around my specific switch, while the other is hole-free and meant for you to use as a template to drill your own mounting holes. During assembly, I discovered that the servo mount was hitting the X-drive belt. To resolve this issue, I had to remove some material from the rear mount. If you encounter similar problems, you may need to adjust your printer's settings or modify the rear mount. This design was created in Sketchup and printed using Simplify3D. I'm still searching for the original sources that inspired my parts and ideas, but I'd like to extend my gratitude to everyone whose work has helped me along the way. Due to my limited access to hardware while deployed in the Middle East, I've tried to reuse as much existing hardware from the Anet A8 kit as possible. The extruder mount uses zip ties to secure the extruder motors and the 50mm fan is friction-fitted into the upper cooling duct. You can add a drop of glue if needed for extra security. The rear mount has no pre-drilled hole, so I drilled one using the fan as a guide; be cautious not to overtighten the bolt. The hot ends I purchased included air fittings, tubing, thermistors, heat cartridges, fan ducts, and cooling fans. I didn't use the ducts. After tightening everything on the hot ends, mine came up about .8mm difference in length from the tip of the nozzle to the end of the housing (minus air fittings). The mount allows each hot end to move up and down about .5mm, making it easy to get them both the same distance from the build plate. For this conversion, I purchased the following items off Amazon: 2 X J head hot ends: https://www.amazon.com/gp/product/B010MSTVZO/ref=oh_aui_detailpage_o06_s01?ie=UTF8&psc=1 1 X MK8 Extruder: https://www.amazon.com/gp/product/B011QCFGPO/ref=oh_aui_detailpage_o06_s03?ie=UTF8&psc=1 M2 / M3 hardware kit: https://www.amazon.com/gp/product/B014OO5KQG/ref=oh_aui_detailpage_o06_s02?ie=UTF8&psc=1 I also purchased the following items, but they're optional (although I'm finding them helpful): Anycubic Barrel Stainless Steel Nozzle Throat with PTFE Tube: https://www.amazon.com/gp/product/B0188G31AS/ref=oh_aui_detailpage_o01_s03?ie=UTF8&psc=1

With this file you will be able to print Anet A8 Dual Bowden Conversion with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Anet A8 Dual Bowden Conversion.