Anet A6 Hot End Mod 3

pinshape

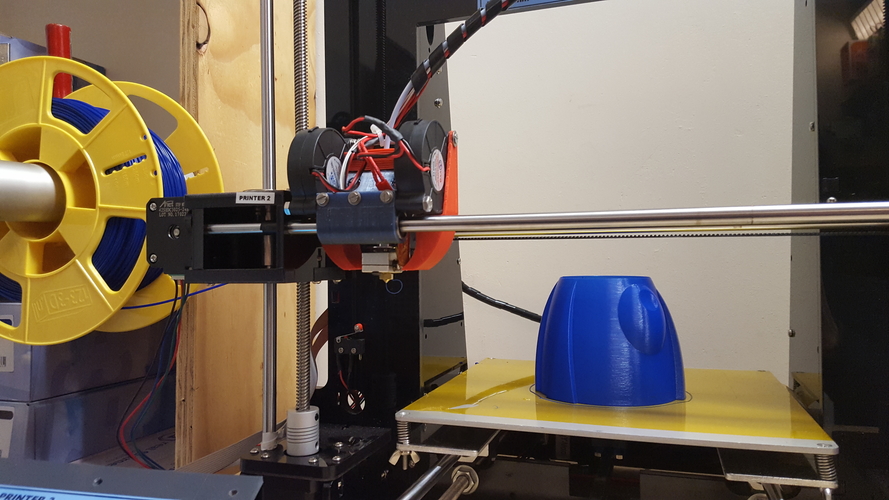

For an even better presentation, visit https://www.designuitinspirati... This is Hot End 3 for the Anet A6. I own multiple Anets and use them primarily for ABS and PET-G printing. However, they're not suitable for PLA due to a lack of cooling fans and heat break design that restricts airflow onto printed parts. The extruder remains mounted on the X-axis, which isn't optimized for speed when printing with ABS. As a result, I've focused on optimizing my other printers for faster ABS prints. Lately, I've been shifting towards PLA due to its cost-effectiveness. This change in focus has given me a compelling reason to upgrade my Anet's hot end and enable efficient PLA printing. My primary objective is to minimize the X-axis weight while incorporating effective cooling for PLA. To achieve this, I designed a Bowden setup and installed "snail house fans" on either side of the X-carriage. By eliminating the cable holder and routing cables directly to the Teflon tube, I've significantly improved airflow. The extruder is now positioned above the controller board, further enhancing cooling efficiency. Additionally, I removed the original housing to reduce weight and improve overall performance. When it comes to printing PET-G with a cooled hot end, results vary depending on object size and shape. Small or rounded objects print well, but larger prints often experience warping issues. For these cases, I prefer using my ABS-specific Anet Hot End mod. If you have any questions or feel that something is missing from this tutorial, please don't hesitate to ask. Here's a comprehensive list of parts used for this project: * 2x Teflon tube holder clips (3-4 mm) * 1 piece of Teflon tube (3-4 mm) compatible with 1.75mm filament * Linear bearings from the Anet A6 printer (LM8UU, 2x) * Extruder driver gear from the Anet printer * Nema 17 motor for extrusion (from the Anet printer) * Spring for the extruder (from the Anet printer) * 2x Snail house fans (one came with the Anet printer) * Hot end assembly (includes heat break and cooling fins, diameter: 22.5mm x 26mm) * Heater block and thermistor from the Anet printer * Filament pressure wheel for extrusion (from the Anet printer) * Fan and holder for hot end (came with the Anet printer's hot end assembly) * M4 hex key head (6mm, came with the Anet printer) * 2x M4 screws x 45mm, along with corresponding nuts * 5x M4 screws x 20mm, accompanied by 3 nuts * 8x M3 screws x 20mm, paired with 5 nuts * 4x M3 screws x 10mm, linked to 3 nuts * 1x Treated rod (80mm long) and corresponding nuts (used 2 M3 bolts instead in the image) The picture illustrates where each bolt and nut should be placed. Please note that I omitted the Teflon tubing from the extruder drawing as well as the spring, and also didn't depict the two M3x20mm bolts securing the stepper motor. Time constraints dictated this creative representation.

With this file you will be able to print Anet A6 Hot End Mod 3 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Anet A6 Hot End Mod 3.