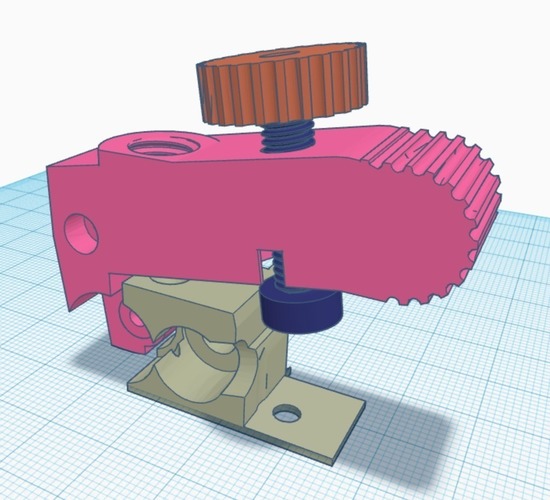

Anet A6 : Feeder improvement for flexible filament

pinshape

This is a significant upgrade for the Anet A6 feeder that allows easy printing of flexible filament. Flexible filament has a tendency to bend and get stuck in the feeding toothed wheel, so it needs to be precisely guided into the hot end without any gaps where it could escape. To achieve this, I designed these parts, which I have used for months with various filaments, both flexible and rigid, without experiencing any feeding issues. As the goal is to eliminate all holes on the feeding path, the "Filament guide.stl" part requires manual adjustment. The path drilled into this part should be done with a 2mm drill bit for smooth filament flow. The mobile throated wheel hole needs to be adjusted using a Dremel tool so that the throated wheel, mounted on the "Pusher.stl" part, just touches the toothed wheel, ensuring strong feeding. To adjust and test the strength, assemble both wheels onto the part and insert a PLA or ABS filament into the path hole. It should grip well without slicing. Once adjusted and set, you won't have to worry about feeding issues for many hours of printing - I've used one of these parts for hundreds of hours with no problems. The "Filament tensor.stl" part is not essential for feeder functionality but serves a purpose in pulling the filament from the spool, reducing bending or stretching. It works well and is recommended to use. Printer Settings: - Printer: Anet A6 - Rafts: No - Supports: Yes - Resolution: 0.1 or 0.2 mm - Infill: 80% (Suggested to be 100% for the "Pusher.stl" part) Post-Printing:

With this file you will be able to print Anet A6 : Feeder improvement for flexible filament with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Anet A6 : Feeder improvement for flexible filament.