Anet A2 diagonal supports

thingiverse

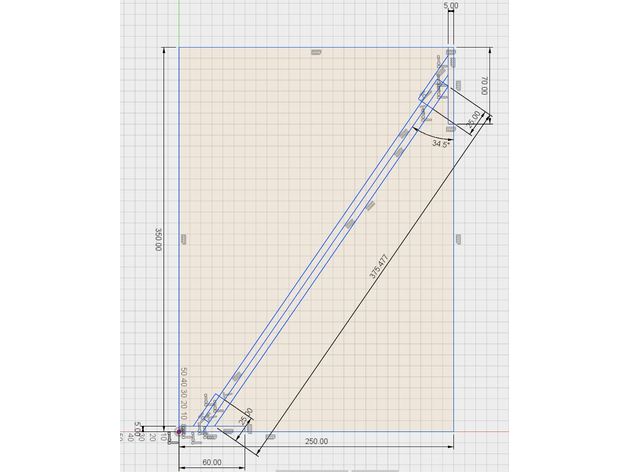

Simple diagonal supports I created to strengthen the frame of Anet A2. They should work equally well on Tevo Tarantula or any similar printer that uses 2020 and 2040 profiles. These are designed for use with 12mm aluminium tube, which can be found at most hardware/building supplies stores in my area. In my setup, the tubes measure 375mm long (325mm visible length +25mm into both mounts), and the entire setup is then 350 mm high and 250mm forward from the frame. You can adjust the tube length to achieve different dimensions. I used M5x10mm bolts and M5 T-nuts to secure it to the frame (4 sets), 5x20 wood screws (4 pcs) to secure it to the base, and M3x3mm set screws (8 pcs total, 2 per mount) to secure the tube into the mounts. These supports really stiffen up the upper end of the frame. There's no need for fancy lower and upper brackets that weigh half a kilo and take days to print. Printer Settings Printer: Anet A2 Rafts: No Supports: Doesn't Matter Resolution: 0.2 Infill: 100% Notes: I printed the pieces in the orientation they come in the STL files, with lower mounts laying down and upper pieces standing up, to minimize overhang angles. I used brim for the upper pieces to prevent them from falling over during printing, and it worked perfectly on the first attempt. Post-Printing The tube holes are designed to be 12.2mm diameter, but I had to use a 12.0 drill to clean them up after printing and shave some material off the holes to make the 12mm tubes fit. I assembled the tubes and mounts first, secured them with set screws so that ~325.5 mm of tube was showing, then mounted them to the plate and frame. It helps to mark the expected height (350mm) and distance from the frame (250mm) on the frame/baseplate first. Mounting is a bit tricky due to two of the screws being behind the tube, but it's doable. To make life easier, I marked the lower mount holes on the base plate first, screwed the screws in once (careful not to go through the baseplate!), removed the screws and then mounted the assembled support. You can fine-tune the angle using the upper support height, I used a metal square tool, measuring on both front and backside of the frame to make sure it's perfect, before fully tightening the upper mount screws.

With this file you will be able to print Anet A2 diagonal supports with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Anet A2 diagonal supports.