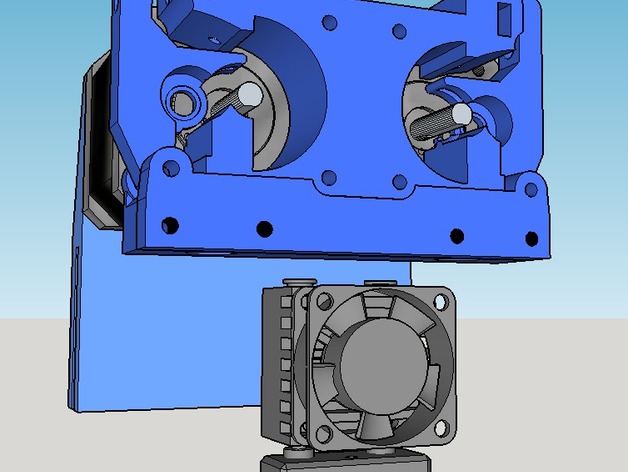

Amadon's Double Bowden Direct Drive Extruder 1.75mm filament

thingiverse

Double Bowden Direct Drive Extruder for E3D Cyclops/Chimera: Designed to Accommodate Any Dual Extruder Setup. To add more flexibility, I have upgraded the idlers with new designs that incorporate bearings on both sides. This ensures they cannot bend over and lose clamping pressure on the filament, enhancing overall performance. Inside this extruder, a 0.4mm thick support material is built-in. However, users must cut it out to get the best results. Unlike other assemblies that require additional slicer support, none are necessary in this case. Two key assembly details include using a washer on both sides of the roller bearing and employing a low-profile nut for efficient operations. Flat idlers face towards motors, with slightly raised sides directed towards the front side. When attaching the motor-side nut, make sure to secure it tightly. These detailed instructions ensure smooth construction and minimize confusion among users. The provided design includes everything needed for this assembly process. To assemble, follow these simple steps: Begin by obtaining the required materials and parts: two NEMA17 motors, MK8 drive gears, M3 threaded rod cut to 75mm long with nuts on both ends, a set of screws (differing lengths), and a MK8 drive gear (in duplicate). Securely attach the rods to the front and back plates via bolts. Use this extruder assembly in conjunction with an E3D Cyclops or Chimera setup. It was originally designed for use with these popular models but is also compatible with any dual-extrusion printer configuration. Mounting motors requires straightforward adjustments. Note that this system fits snugly over the aluminum frame of a Prusa i3 metal. Those needing to adapt their printers should feel free to share information so I can provide a custom solution. At the base, two retaining clips are embedded for accommodating Bowden tubing retainers supplied with Cyclops extruder. To adjust tightness of clips and threads, apply tape (pipe or electrical). Use thin washers between idlers and roller bearings when installing new bearings because dragging can cause unwanted issues. Low-profile nuts should always be used; grind off the screw if necessary to accommodate its placement around the motors' edges. Finally, M4 tension springs secure M4 nuts within a recess in the extruder body, thus preventing it from becoming misaligned. Any favorite Chimera/Cyclops mounting system will work here - choose whatever fits your requirements best. Before beginning assembly and attachment processes please review instructions: If back support doesn't align on an edge, use printer orientation wisely to ensure smooth build-out operations - sides, in other words. This particular adjustment may improve its resistance when under heavy stress (tension, compression). Print in the direction that supports this stability most naturally

With this file you will be able to print Amadon's Double Bowden Direct Drive Extruder 1.75mm filament with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Amadon's Double Bowden Direct Drive Extruder 1.75mm filament.