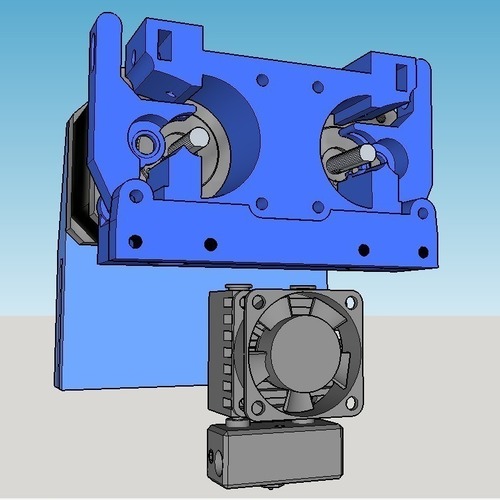

Amadon's Double Bowden Direct Drive Extruder 1.75mm filament

pinshape

Double Bowden direct drive extruder. I designed this for the E3D Cyclops/Chimera but it can be used with any dual extruder setup. Added new idlers on June 6, 2016, which have support for bearings on both sides to prevent bending and loss of clamping pressure on filament. A 0.4mm thick support material is built in that must be cut out, no additional support needed from slicer. Use a washer on both sides of the roller bearing with a low profile nut. The flat side of idlers should face motors, slightly raised sides towards front, put nut on motor side. This assembly uses same parts as this design except screws that hold it together might be different lengths and some things need two of, like idler bearings and MK8 drive gears. This uses two NEMA17 motors and two MK8 drive gears. The whole thing is easiest to assemble using M3 threaded rod cut to length going through motors and front and back plates with nuts on ends. Cut rods to about 75mm long, remove all four screws from motors and screw rods through motors with ends sticking out both front and back to attach printed parts. It's made to slip over the top of aluminum frame of a Prusa i3 metal. If you need another way to mount motors to printer let me know and maybe I can throw something together. The holes at bottom are for Bowden tubing retainers that come with a Cyclops extruder. On my printer, the holes printed perfectly, but if your printer doesn't like printing holes smaller than model slightly they might be loose. You could tighten them up by putting some pipe tape or electrical tape around threads. The front retainer piece pinches threads to hold them tight so you don't have to screw them in place and mess up threads. The idlers use a 5x10x4 roller bearing and a short M5 cap head screw. I recommend small washers between idler and bearing because when you tighten the M5 screw the roller bearing might drag on printed idler. Get thin washers, 10mm dia. The nut on back MUST be low profile as well or it will run into lip on front of motors. You may have to grind end of M5 screw flush with nut as well. The tensioners for idlers are M4 screws with a spring on them and M4 nuts inserted into recess at top of extruder body. Use this or another favorite mount for Chimera/Cyclops, any will do. Message me with questions! I recommend printing the back part that slips over printer frame on its side, not standing up. If you print it standing up, the grain of layers makes it very weak and I dropped assembly and it broke along motors edge. If I'd have printed it on its side, the layers would be perpendicular to direction of strain. Even though there's an overhang in back, just use support material. There won't be much. If you set slicer to leave 0.8mm of space between model and support it should pop out easily.

With this file you will be able to print Amadon's Double Bowden Direct Drive Extruder 1.75mm filament with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Amadon's Double Bowden Direct Drive Extruder 1.75mm filament.