Air Engine

thingiverse

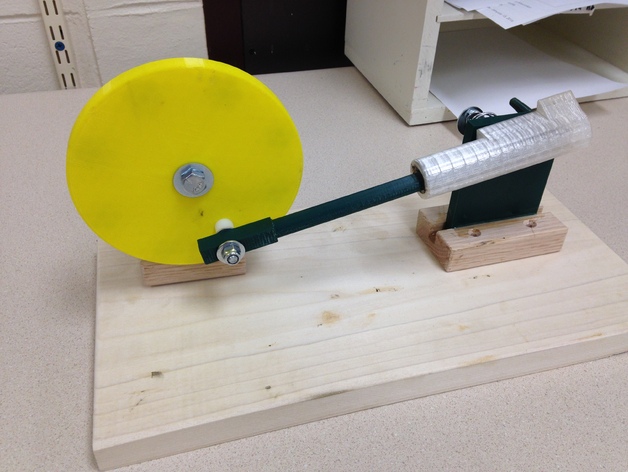

I am a Technology Education Teacher based in Green Bay, Wisconsin. I designed an engineering project for my students that involves building a small engine using solidworks and 3D printing technology. The project allows students to learn the fundamentals of designing with solidworks, working in teams, and solving problems through trial and error. The students divide into groups of two and work together to design and build the components of the engine, including the cylinder, piston, flywheel, and supports. They use parameters set by the teacher to ensure that their designs meet specific requirements. Once the designs are complete, they save them as STL files and print all the parts using a MakerBot Replicator 2 printer. After printing, the students assemble the engine and test its functionality. This process often requires reworking and problem-solving, but it allows students to learn from their mistakes and develop persistence and critical thinking skills. The project is designed to simulate real-world engineering experiences, where design iterations are common and problem-solving is essential. The printer settings used for this project were standard, with a resolution of 0.20mm and an infill percentage of 10%. However, the students found that printing the cylinder in a front-to-back orientation resulted in better quality prints. Assembling the engine requires about $2 worth of hardware, which includes wood screws, fender washers, spring clips, hex bolts, lock nuts, and copper pennies. The engine is lubricated with light grease, and the flywheel and piston support are glued into anchor blocks using two-part epoxy glue. The final result is a functional air engine that runs smoothly, thanks to the students' hard work and dedication. This project is an excellent way to teach students about the design process, problem-solving, and critical thinking skills, making it an ideal activity for advanced 7-8 grade after-school groups or entry-level engineering courses for 9-12 grade students. To achieve this project's objectives, I would: * Lecture on the design process and have a discussion with the students to ensure they understand its importance. * Divide the students into small groups of two to four and assign each group a set of plans for the engine. * Have the students work together to design and build the components of the engine, ensuring that they break up the work evenly. * Assemble the separate parts as a group and check clearances and positioning of the valves. * Encourage brainstorming to fix any potential problems and have the students test and evaluate their physical engine. * Depending on the outcome, have the students re-engineer some parts until it works. Enrichment activities include: * Having students build the engine from a physical model previously made and measure the parts before building them from scratch. * Having students change the bore and stroke of the engine while still using my plans.

With this file you will be able to print Air Engine with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Air Engine.