Adjustible Venturi

thingiverse

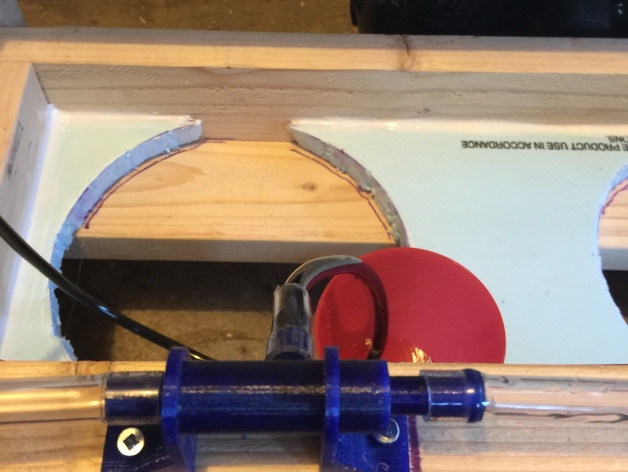

This is a flexible project designed to help students measure flow rate, lift, and pressure ratios, laying the groundwork for fluid dynamics learning. It can utilize any fluid compatible with the printing material as the driving force. Print Settings Printer Brand: Robo 3D Printer Model: R1 ABS + PLA Rafts: Not required Supports: Yes Resolution: .2mm Infill: .4 Notes: This requires printing with an insoluble filament. I used PETG. How I Designed This Venturi Design I created this design in Tinkercad, incorporating entry and exit angles based on Escbach's Handbook of Engineering Fundamentals, 3rd Edition, 1975. As a substitute for a submersible pump, it allows for the passage of debris. Custom Section Project: Adjustable Venturi Objectives: I aim to help students learn alternative methods for creating suction and lift, enhancing their understanding of fluid dynamics. Audiences: List the suitable grades, ages, or skill levels for this project. Preparation: A motive source, substrate to be moved, and a collection container are required. Students will also need 3/8" I.D. tubing. Steps: The initial design demonstrated that the motive force could not generate suction due to lack of direction. In MK2, a separate motive nozzle was added for calibration and flow control. I recommend introducing venture design basics before the lab. Results: At 0.017 mpa, I achieve approximately 4 gallons of fluid movement daily. This can be increased with more motive force; however, printing in 100% infill is recommended for stability.

With this file you will be able to print Adjustible Venturi with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Adjustible Venturi.