Adjustable Thrust Angle Airboat

thingiverse

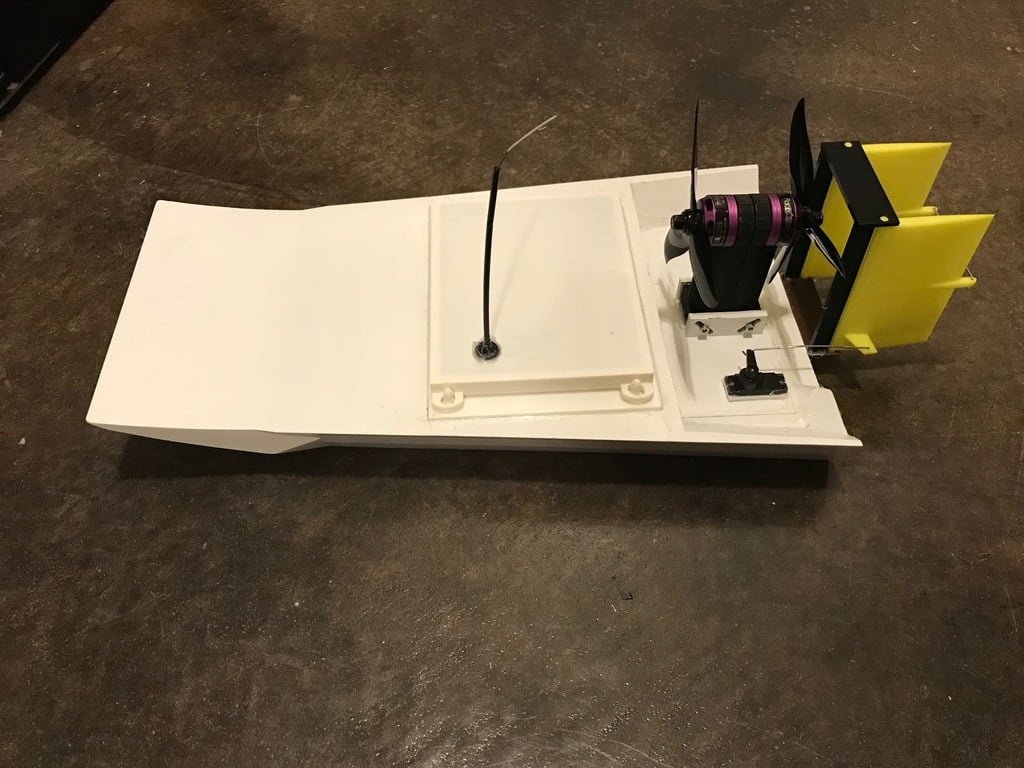

Balance and thrust angle are critical for airboats. After scouring online resources, I discovered that no solution addressed changing the thrust angle, prompting me to design my own setup. The motor mount can be tilted forward to correct plowing or back to rectify porpoising. By setting the back deck low in the hull, the thrust line is brought closer to center. Experiment with battery positioning to achieve optimal handling. For me, this meant aligning batteries parallel to the long axis and centered within the hull. This model can be constructed using one or two motors. I created a blank to install in the front motor post for aesthetic/aerodynamic purposes. It's essential to configure the motors so they spin in opposite directions, canceling out each other's torque. The motor mounts were printed in ABS, scaled specifically for this design. Other components were manufactured with PLA, although PETG could serve as a suitable alternative if ABS is inaccessible. To guarantee water resistance, ensure the back deck remains entirely waterproof since water inevitably seeps onto this deck at times. I applied hot glue around motor wires and epoxy around ESC sinks. Future updates may include eliminating the notch in the transom; only time will tell. The hull was printed with 5% infill and a single shell to minimize weight. A coat of paint serves as an additional sealant for any small holes. Before assembly, I submerged the empty hull in water, added weight, and conducted an overnight test to verify leak resistance. Once confirmed leak-free, I proceed with assembly. Hot glue is used to secure top plates due to its holding properties and ease of disassembly. Epoxy joins the two halves of the hull, followed by sanding flush before painting. When working with epoxy, it's essential to avoid applying excessive heat during sanding, which can warp the hull quickly. To assemble the rudder, apply epoxy to join the top/bottom portions together, ensuring the rudders are in place beforehand. Epoxy or silicone is used to seal holes in the back of the hull before driving screws to guarantee watertightness. Verify that the boat's bottom remains flat, particularly at the rear edge, as this aspect significantly impacts performance. To ensure a smooth finish, I applied high-build primer and block-sanded the assembled model twice before applying the final coat of paint. This process yields an exceptionally flat bottom, resulting in improved boat performance. Two additional back plates were included: one with only one ESC heat sink hole and another without any holes for customization purposes.

With this file you will be able to print Adjustable Thrust Angle Airboat with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Adjustable Thrust Angle Airboat.