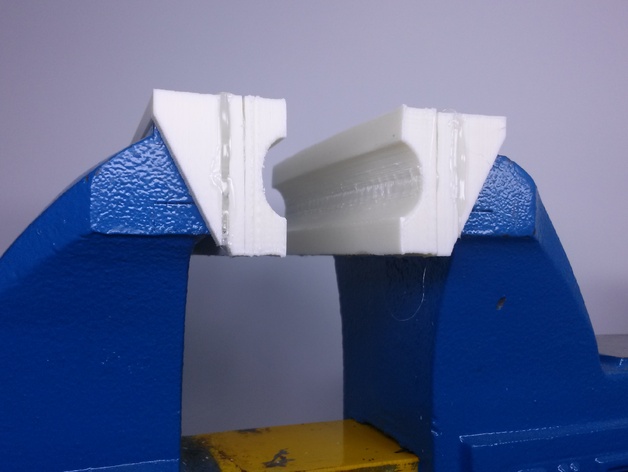

Adjustable Slip-On Pipe-Clamp Vise Pads

thingiverse

These are slip-on vise pads that fit like a glove in OpenSCAD, making it a breeze to adjust them to suit your needs. If you want to hold pipes securely without leaving unsightly jaw marks on the pipe itself, these pads are just what the doctor ordered. They wrap snugly around the entire jaw of your bench vise, so they won't come loose during use. To get the perfect fit for your vise's jaw dimensions, simply tweak the viseX, viseY, and viseZ parameters - check out the diagrams above for more info. Don't forget to add a 1% buffer for ABS shrinkage. The thickness of the top, bottom, sides, and face can be adjusted in millimeters to suit your needs. Here are some print settings you might want to consider: Printer: No-name i3 clone Rafts: Not necessary - just use a 10mm brim to minimize warping Supports: Yes - print them face-down for best results When clamping the vice, make sure the clamp is pressing on the "face" of the grain (layers) and not on the edges. This will prevent cracking under pressure. To avoid warping, keep the temperature hot throughout the printing process. Consider making the overhang very short or eliminating it altogether - you can check out post-printing instructions at http://www.thingiverse.com/thing:1933068 to see how this affects warping. These pads are built for compression and will hold up under high pressure if printed with 30% infill, 1.6mm walls, and 1.6mm top/bottom thickness. In the OpenSCAD script, you can increase your vise dimensions by a percentage to account for shrinkage - I recommend adding 1% to your jaw dimensions when printing with ABS. This will give you a snug fit without any slop. To change the size of the pipe you can hold, simply adjust the value of pipeRad to the radius of the pipe (currently set at 0.5" or 25.4/2 mm for a 1" pipe). The pipeOffset and faceMargin values will automatically adjust - leave some gap between the pads when clamping down on a pipe. Post-printing, you can remove supports by prying them off with a pocket-knife. Notice how severe warping is on the face - this might be due to the pipe-shape and long overhang in the back. To fix cracking, use tick marks to match up the original orientation, split the piece along the main cracks, and then glue it back together using hot-melt glue. Reducing cracks can be achieved by setting the overhang to a very small value - this should minimize cracking problems. If cracking is severe, simply fill the cracks with glue.

With this file you will be able to print Adjustable Slip-On Pipe-Clamp Vise Pads with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Adjustable Slip-On Pipe-Clamp Vise Pads.