Adjustable Extruder Latch

pinshape

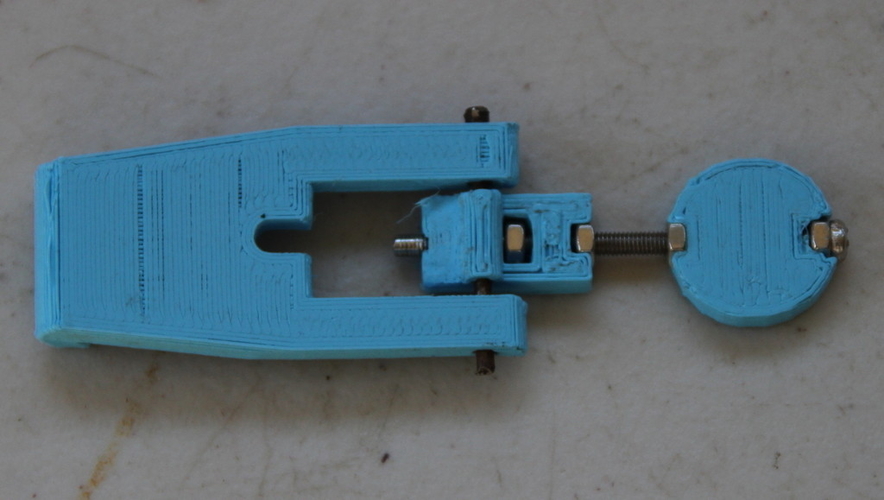

Instructions for Adjustable Extruder Latch Based on Eric's Wade's Collaborative Dual Feed Extruder To create an adjustable extruder latch, I divided the latch into three parts and inserted several captive M3 nuts that hold an M3 bolt acting as an adjuster. This allows you to set the pressure exerted onto the filament to a precise amount. I positioned an M3 nut under the lip on top of the extruder by drilling a 3 mm hole about 1-2 mm deep, heating the M3 nut up, and placing it over the hole. See picture 3 for reference. To adjust the latch, swing it into position, align the M3 adjuster bolt with the captive nut under the top lip, and turn the latch key to set the desired holding force. I used a bit of glue where the bolt head meets the first captive nut on the turn key to prevent it from unwinding as you tighten the latch. The captive M3 nut under the lip effectively holds the latch in place and prevents it from springing up. So far, this setup seems to be working well. For other files needed to build this adjustable extruder latch, check out Eric's Wade's Collaborative Dual Feed Extruder.

With this file you will be able to print Adjustable Extruder Latch with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Adjustable Extruder Latch.