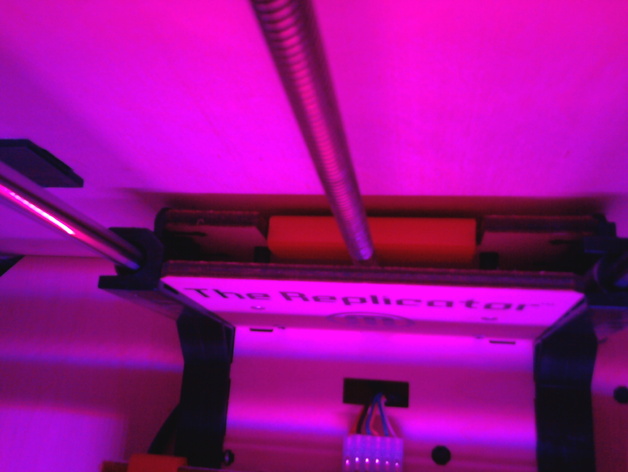

Acrylic plattform upgrade for the Replicator

thingiverse

This modification for a Replicator 3D printer involves attaching a 3mm thick acrylic sheet to the platform using four clamps. PLA prints bond better to acrylic than to painters tape, reducing curling and warping. After printing, the acrylic sheet is removed and bent gently in different directions to loosen the print before snapping it off with fingers. Acrylic sheets are cheaper to replace than aluminum platforms if damaged. Temperature and distance between nozzle and acrylic sheet can be adjusted for better bonding control, enabling printing of supported structures without rafts or managing stubborn prints that curl. However, not all acrylic sheets work equally well; "Perspex" is currently recommended but must be sourced individually. The long distance piece must fit tightly next to the Z-endstop, and printed parts should be trimmed for smoothness. Clamps should be placed carefully to avoid collisions with extruders. Extruding too close to the acrylic sheet may fuse it permanently to the print; start at double the normal distance and adjust carefully. Lastly, ensure the platform surface is properly degreased before printing.

With this file you will be able to print Acrylic plattform upgrade for the Replicator with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Acrylic plattform upgrade for the Replicator.