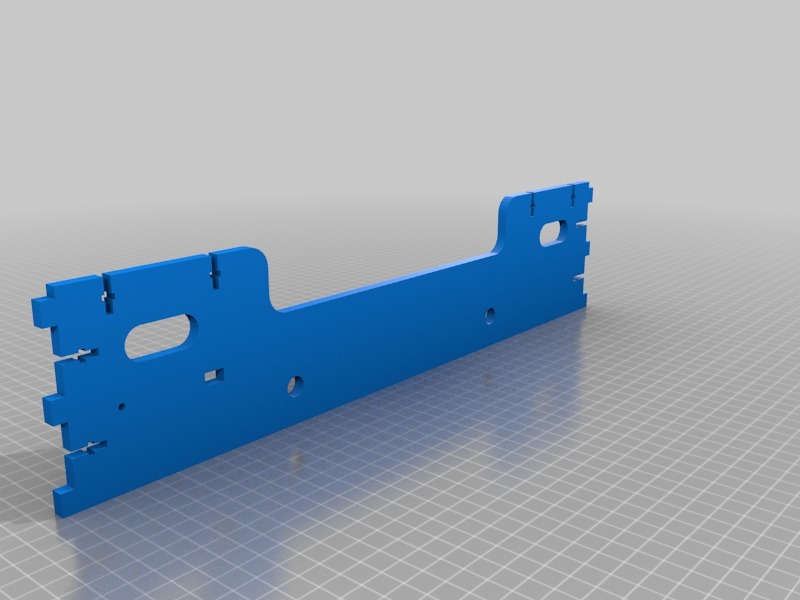

Acrylic Part 8 - Bottom Support

thingiverse

Acrylic Part 8 - Reinforcing Base Manufacturing acrylic parts requires a strong foundation to ensure stability and durability. In this step, we will focus on creating the bottom support, which is essential for holding the entire structure together. This critical component will provide the necessary rigidity and support to prevent the part from warping or bending under stress. To achieve optimal results, it's crucial to pay close attention to detail during this process. The bottom support must be carefully designed and crafted to fit snugly within the acrylic frame, ensuring a secure and seamless connection. Any imperfections or misalignments could compromise the integrity of the entire structure, leading to costly repairs or even complete failure. Using high-quality materials and precision tools is essential for creating a robust bottom support that can withstand various environmental conditions. The material chosen should be able to resist moisture, temperature fluctuations, and other external factors that may affect its performance. By selecting the right material and executing the manufacturing process with care, we can ensure that our acrylic part meets the required standards of strength and reliability. In this tutorial, we will cover the steps involved in creating a sturdy bottom support for our acrylic part. From design to assembly, we will provide a comprehensive guide on how to produce a high-quality reinforcing base that meets the demands of modern applications. By following these instructions carefully, you'll be able to create a reliable and durable bottom support that enhances the overall performance of your acrylic part.

With this file you will be able to print Acrylic Part 8 - Bottom Support with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Acrylic Part 8 - Bottom Support.