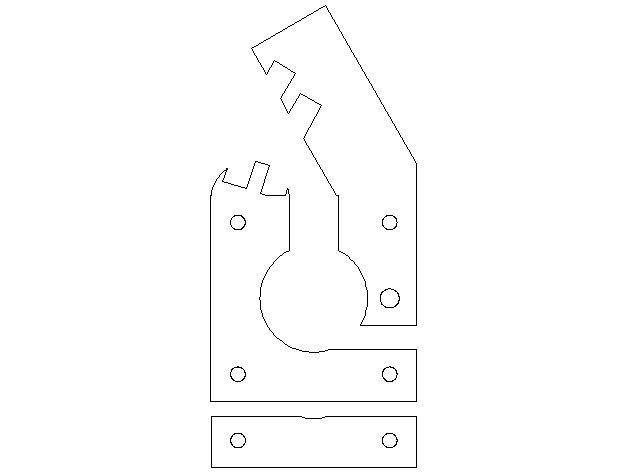

Acrylic Laser Cut Direct Drive Extruder

thingiverse

This direct-drive extruder, designed for acrylic cutting, has been updated on April 10. Due to limited space for a pneumatic push fit connector, the bottom of the extruder has been replicated. By adjusting the size of the drive gear/hobbed gear, you can cut multiple pieces of the bottom horizontal bar in the design, stacking and adhering with CA glue or epoxy during assembly. Measure and drill/tap the center of the filament to accommodate the push fit connector's bottom. A 4mm to M5 push fit connector was used for a snug 4 mm PTFE tube fit, acting as the bowden tube. The hole for the M5 screw fitting the bearing has been reduced in diameter (3.9 mm) to ensure sufficient acrylic for M5 thread tapping. Other changes include increased spring notch size for strength. All parts were designed in Openscad, with DXF projections available. Use at least 8mm thick acrylic for stiffness and a 625ZZ bearing, which can be sourced from window rollers or hardware stores. Avoid mounting directly on the motor due to shaft interference. Utilize a spring to maintain even filament tension between the provided arm notches and mount.

With this file you will be able to print Acrylic Laser Cut Direct Drive Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Acrylic Laser Cut Direct Drive Extruder.