96mm EDF for a 540 motor

thingiverse

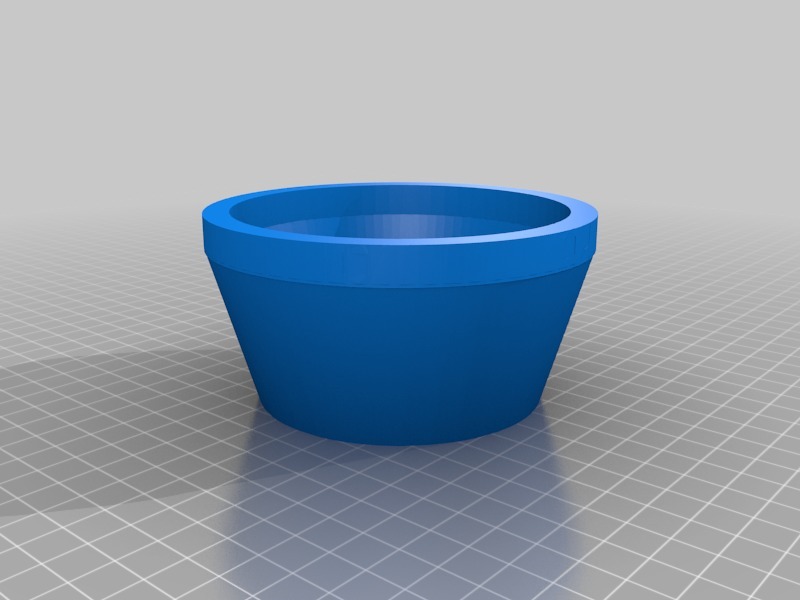

Motor housing will adhere firmly to exhaust section after fan and motor installation is complete. The tight fit of the fan requires careful handling, potentially causing it to catch during initial spool-up. Allowing the fan to gradually wear itself in at low RPMs for a few minutes or until noise subsides is recommended. Upon RPM increase, catching may occur again, but this issue will soon resolve. A precise tolerance is essential to achieve high efficiency. Infill settings should not be compromised; breaking up at 20,000RPM's is undesirable. The fan features the shaft nut recess facing away from the motor. Print the exhaust housing upside down as depicted in the image. Other components may be printed unchanged. Added V3.0 motor housing and intake with significantly tighter induction compression tolerance.

With this file you will be able to print 96mm EDF for a 540 motor with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 96mm EDF for a 540 motor.