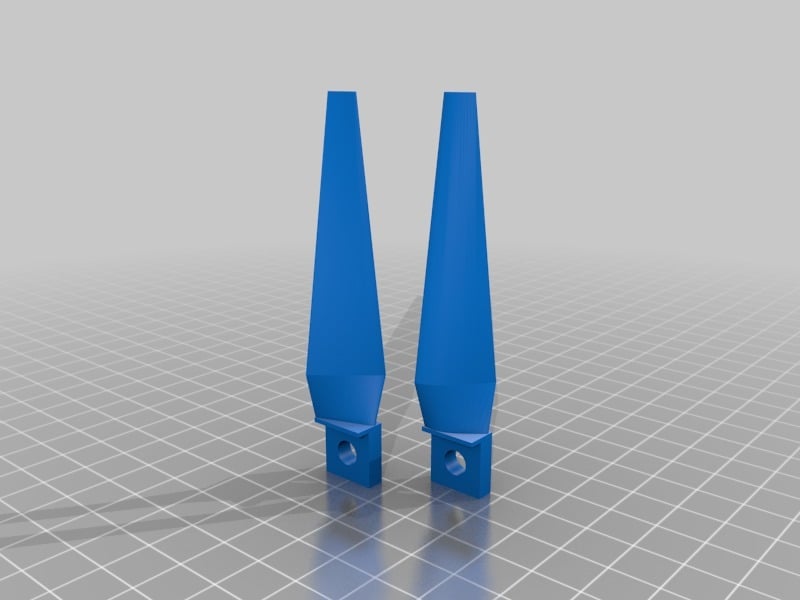

6x4 Propeller

thingiverse

This is a completely experimental endeavor. Props spin at incredibly high speeds, posing significant risks of injury. To test props, one must first obtain precise prints, which can be extremely challenging. I have printed a motor mount and secured it to a block of wood, then attached the propeller to a 2200kv motor in a push orientation. The wood block is connected to an old scale, which I carefully zeroed out before running the propeller at maximum RPMs to measure the force exerted downward in pounds. As part of this experiment, I have encountered issues related to print quality. It took approximately five or six attempts to perfect the printing process, resulting in minimal cleanup required. The second-to-last prop I printed registered only 0.8lbs, but it suffered from a critical flaw: the center hole for the shaft was slightly too large, causing the blades to become misaligned and rendering the entire assembly unbalanced. A breakthrough occurred with the last propeller print, which yielded a snug fit on the shaft. However, I failed to test this prop on my scale rig initially, instead relying on personal experience with model planes to gauge its power. This decision was reckless and posed significant risks of injury. I held onto the wood block while ensuring the motor faced me, with the propeller parallel to my body, in case a blade snapped loose. Unfortunately, I did not record the results, but here is what I observed: as I gradually increased the throttle, feeling for any signs of imbalance, I eventually reached maximum RPMs without incident. However, this was an error on my part - I should have continued to incrementally increase the throttle. The moment I hit full throttle, the entire rig suddenly exerted a tremendous force in my hand, making it extremely difficult to control. One of the blades may have snapped, although I don't recall any abnormal vibrations. Regardless, the outcome was catastrophic: the motor, mount, and screws were ripped from the wood board, causing the propeller to shatter on impact. Fortunately, I escaped injury, but I did find a sharp shard across the yard. In retrospect, I should have used longer and larger screws. Despite this setback, I believe the last propeller print performed admirably in terms of force exerted, and I plan to print another one for proper testing on the scale rig. In light of this experience, I may consider configuring some protective barriers around the test area to prevent potential injuries from stray blades. My current setup is not ideal for scientific measurements, but my primary goal remains comparing 3D-printed props against store-bought alternatives and assessing their strength. Feel free to download and experiment with these designs, but please exercise caution when handling high-speed propellers.

With this file you will be able to print 6x4 Propeller with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 6x4 Propeller.