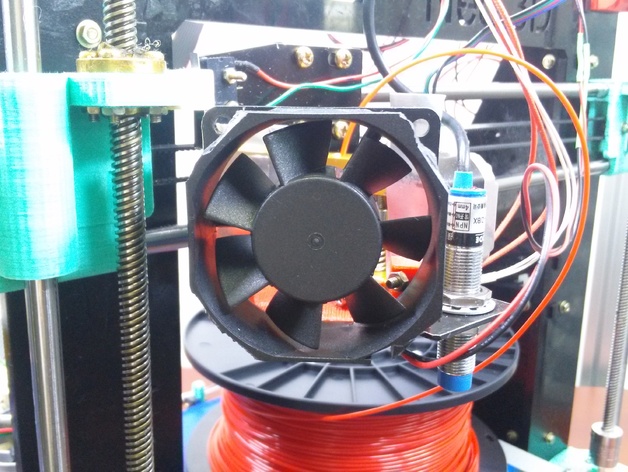

60mm Fan Mount For 31mm Direct Drive Extruder

thingiverse

Here is my total solution for heat creep. Not only does it effectively solve any and all jamming issues I've had with ABS, it's also extremely cheap and simple to implement. 3D printer designs are plagued with the ubiquitous 40mm fan that doesn't effectively cool the extruder, nozzle throat, or filament which leads to inevitable jamming. All over the internet and 3D printer boards you can find elaborate fixes such as fancy heat sinks, geared extruders, ad nauseam. My solution is to just stick on a bigger fan. This solution is directed towards users who print in ABS using cheap knock-off i3 clones using some kind of cover or hood to keep parts from warping (like me). This solution requires 1 60mm fan, 7 M3 screws & nuts, thermal paste, and a 28mm nozzle throat. This solution should work for pretty much any knock-off direct-drive extruder which uses 31mm stepper motor mounts. Optionally, you can add a second fan and switches for not too much more moolah. For more details, read below. Actual results: If you print your i3 in an open configuration (no hood or cover), then you will need to raise your heater to 260 deg C and slow your printer down to 10-15 mm/s. Your throat will be too cool to run any faster than that. I made a cardboard cover for my printer so I can hotbox it for ABS prints. If you cover your printer after the first layer, you can set your heater to 240 deg C from the start. (As of 2016/12/01) I run my printer at 50 mm/s all day long. I always run the heatbed at 90 deg C. I turn the fans on after covering my printer and that's when the magic happens. Step 1: Prepare Your Printer Before we start, make sure your printer is clean and free of any debris. Also, make sure you have a spare set of M3 screws & nuts in case something goes wrong. Step 2: Remove the Original Fan Remove the original fan from your printer and set it aside. You won't be needing it anymore. Step 3: Install the New Fan Install the new 60mm fan on the tensioner body, making sure it's securely fastened with M3 screws & nuts. Step 4: Add Thermal Paste Apply a thin layer of thermal paste to the nozzle throat and make sure it's evenly spread. This will help dissipate heat more efficiently. Step 5: Install the Windscreens Cut out small pieces of aluminum or plastic to fit over the nozzle throat. These windscreens will direct the airflow upwards, keeping your printer cooler. Step 6: Secure the Windscreens Use M3 screws & nuts to secure the windscreens in place. Make sure they're tightly fastened so they don't come loose during printing. Step 7: Add a Second Fan (Optional) If you want to cool your driver circuits even further, you can install a second fan. This will help prevent overheating and ensure your printer runs smoothly. Step 8: Test Your Setup Once everything is installed, turn on your printer and test it out. If everything works as expected, you should see a significant reduction in heat creep and jamming issues. If, for some reason, this solution doesn't work out for you, don't worry! You can always return your machine to its original configuration with minimal money lost. Good luck!

With this file you will be able to print 60mm Fan Mount For 31mm Direct Drive Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 60mm Fan Mount For 31mm Direct Drive Extruder.