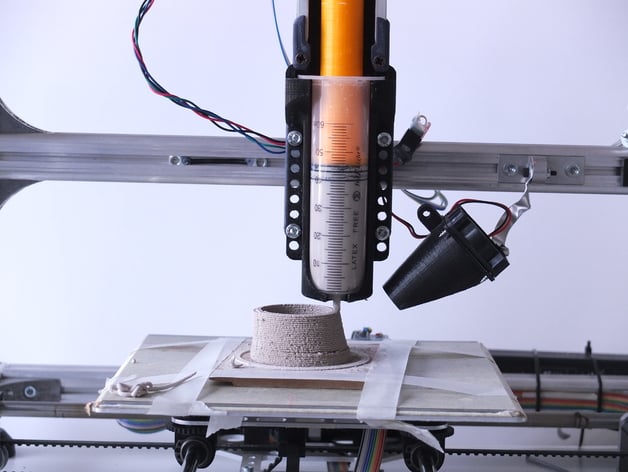

60ml Syringe Extruder for Liquid Deposition Modeling - LDM

thingiverse

Here's an updated version of our experimental syringe extruder designed specifically for a 60ml syringe - perfect dimensions for our printing needs. This syringe model is a luer lock type, allowing you to utilize numerous nozzles from the luer lock system. This extruder is engineered for use with a 3Drag printer (K8200), but you can easily adapt it to other systems by creating a customized mount for your machine. The 3Drag printer features a moving bed, so our extruder remains stationary during print sessions without experiencing issues related to moving weight. If using this extruder on alternative printer models, remember to slow down all head movements, including print speed and travel speed. The gear reduction ratio of 5:1 is suitable for printing in clay but may not be enough for more viscous materials. We chose this ratio due to dimensional constraints with the 3Drag printer; however, a 6:1 or 7:1 ratio is recommended for other machines. To assemble our main body design, you'll need to print two large parts (approximately 30cm in length). In the future, these two smaller components will be provided as separate pieces for use with the most common FDM printers. **Instructions** **You Will Need:** - A 3Drag printer (available at Futurashop - https://www.futurashop.it/3d-e-cnc/stampanti-3d/stampanti-3d-1/3drag-stampante-3d-versione-1.2-in-kit-7350-3dragk) - 6 x M3 bolts and nuts (30mm) - 2 x M3 bolts and nuts (20mm) - 1 x M8 x 170mm rod - 1 x M8 nut - 1 x 608zz bearing - 2 x C-profile pieces (133mm long, 6x6x1 thickness) - 4 x self-tapping screws (diameter 3mm, length 15mm) - Numerous Luer Lock 60ml syringes (Inj/Light, available at Doctorshop - http://www.doctorshop.it/Prodotti/Siringa-INJ-LIGHT-latex-free-a-3-pezzi-da-60-ml-cono-luer-lock-senza-ago-6400048) **Printer Setup:** To properly calibrate your extruder: 1. Determine the correct E-step for your extrusion stepper (our recommended value is 12500 steps per millimeter of filament). 2. Slow down your extrusion speed to around 0.5mm/s. 3. Try to extrude 10mm of material and measure its movement using the syringe. **Calculation Formula:** To find the new E-step, you will need to solve the formula: NewEstep = OldEstep x NominalDistance (extruded from software) / MeasuredDistance (actual movement) Once close to the correct value, try bigger extrusion distances such as 50mm or 100mm for a more precise calibration. **Slicer Software Settings:** 1. Set filament diameter to 2.9mm (inner diameter of the syringe). 2. Set nozzle size around 2mm (you can adjust it slightly to match real values). **Checking Syringe Capacity:** To verify that you have enough material for your print, use the software Cura, which will indicate how many meters are used for each print job. Keep in mind that the syringe is approximately 100mm long, so only use a maximum of 0.1m for any print.

With this file you will be able to print 60ml Syringe Extruder for Liquid Deposition Modeling - LDM with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 60ml Syringe Extruder for Liquid Deposition Modeling - LDM.