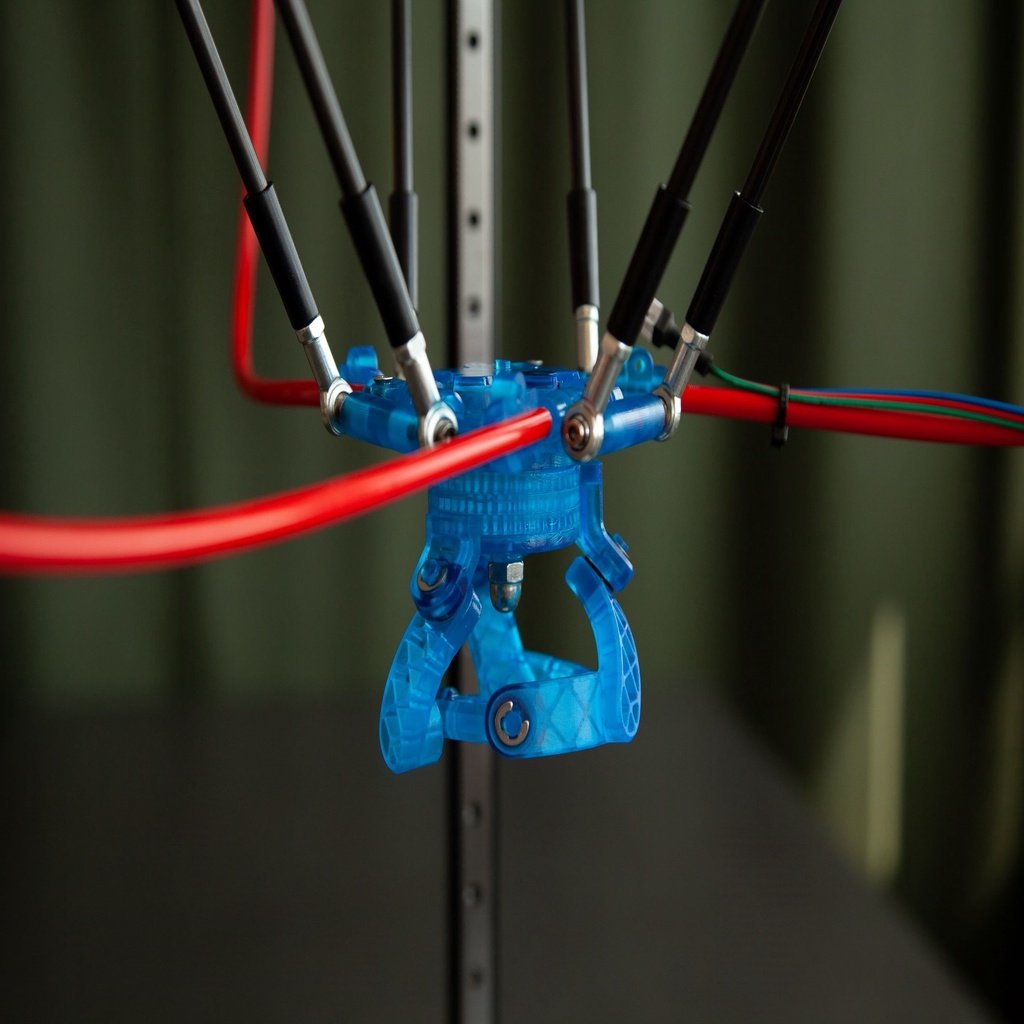

6-Axis End Effector for 3D Printer

thingiverse

**Turn Your Delta 3D Printer into a Budget-Friendly 6-Axis Robot.** This repository contains a coaxial Spherical Parallel Mechanism (SPM) module, designed to replace the end effector of a Delta 3D printer, effectively adding three more axes to the machine. Compare this to robotic arms that can cost up to $20,000 each; you can build this version of a 6-axis robot for under $500 (printer, hardware, and print costs included). Compared to robotic arms, SPMs offer better performance regarding positioning accuracy, speed, force application, and payload-to-weight ratio. This project was made possible by the generous support of SPACE10 through a research residency program in summer 2019. **Hardware Requirements:** * Anycubic Linear Plus or equivalent printer + This system was chosen for its fast Z feed rate and linear rail for sturdy linkage (vs magnetic) * Azteeg X3 Pro or equivalent board with support up to 6 stepper motors * Zesty Drive Cables x3 * Stepper motors x3 * Flexible drive shaft x3 * Retainer rings/E-clip M5 x6, M3 x4 * M3 screws **Fusion360:** Download the .f3z or go to https://a360.co/2IaXe86. To use the Fusion 360 file, go to File -> Open and choose the .f3z file. Modify parameters to change the design to fit your use case. **3D Print Guide:** This version was designed to be printed on an SLA printer. Avoid placing support on mating surfaces. For tighter joint fit, print parts with high-hardness resin. Tough resin (e.g., Formlab Tough) might result in loose joints. **Assembly Guide:** Consult the explode diagram or https://a360.co/2IaXe86 for assembly order. **Important!** Lubricate before assembly! Tight fits could melt together under high friction. Apply PTFE lubricant or low-viscosity lubricant to contact areas. Remove any traces of support on contact surfaces to reduce wearing. **Software:** * This 3-DOF SPM end effector can be controlled by any 6-axis firmware or with Repetier6X (https://github.com/anthonychukh/Repetier6X) * Tool path can be created with SeastarNC, a Rhino Grasshopper plugin for 3D-printer-based robotic control (https://github.com/anthonychukh/SeastarNC) Since most firmware do not support SPM, SeastarNC has built-in components to precompute rotational input for a specific orientation. <img src="https://github.com/anthonychukh/CoaxialSPM/blob/master/Resources/IMG_3040.jpg?raw=true" height=350 align="middle"> <a rel="license" href="http://creativecommons.org/licenses/by-nc-sa/4.0/"> <img alt="Creative Commons License" style="border-width:0" src="https://i.creativecommons.org/l/by-nc-sa/4.0/88x31.png" /></a> <br/> This work is licensed under a <a rel="license" href="http://creativecommons.org/licenses/by-nc-sa/4.0/">Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License</a>. --- **!!!CAUTION!!!** Working with electronic devices can be hazardous. Always take precaution accordingly and make sure you are well-trained and informed to work on the specific system. Failure to operate your machine correctly could result in hardware damage and/or serious injuries.

With this file you will be able to print 6-Axis End Effector for 3D Printer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 6-Axis End Effector for 3D Printer.