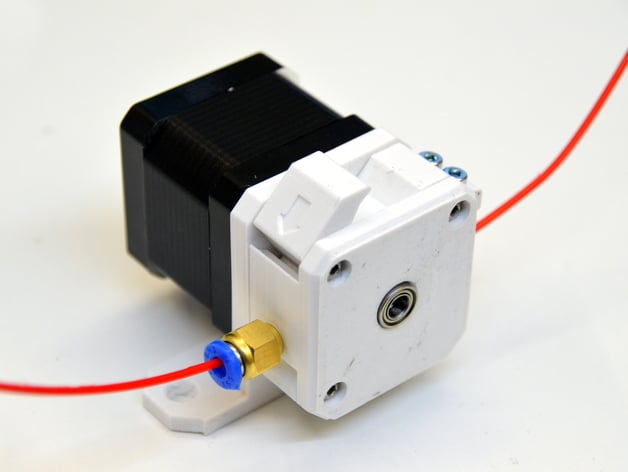

3Dator Bowden Extruder

thingiverse

This is the Bowden type extruder. It's designed to be in a compact form factor, suitable for use with hard filaments like old PLA but also capable of printing flexible materials such as Ninjaflex. The extruder uses 1.75mm filament. With the opener, you can release stress from the filament and change it quickly. The parts are designed to be printed without supports. It can be mounted outside your printer using an adapter. The adapter mounting holes are compatible with the Airtripper Bowden Extruder. Alternatively, you could mount it inside your case like in the 3Dator. The stepper motor goes inside and the extruder outside; a material spacing of 4-5mm is recommended. See how it's assembled here: http://wiki.3dator.com/index.php/Bauanleitung/en#Extruder. See the printer in action printing Ninjaflex here: https://www.youtube.com/watch?v=mxCev5Obq2g. If you don't want to purchase all parts separately, you can buy the extruder here: https://3dator.com/en/shop/3dator-extruder/. Updates: 24.04.2016: Filament channel optimized for better flow. 09.08.2016: Again, filament channel optimized (works best with mk7 gear for 1.75mm filament). Added a file containing the complete extruder ready to print. Added a hook with a hole to observe your mk7 gear and check its alignment (Thanks to 50koruny for the idea). Added a mirrored version for dual extruders in our github repo: https://github.com/3Dator/3dator/tree/master/stl/extra/extruder_mirrored. 23.03.2017: Updated the tightener to use M3 self-locking nuts (we noticed that square nuts are too loose and won't always remain in position). You can still find the old file on github: https://github.com/3Dator/3dator/blob/1e32c3fe1a329b2f864e2268b2501e233c2439be/stl/extruder/tightener.stl. 22.08.2017: Updated adapter.stl to be more usable; now a step file is also included in our git repository. You can find the complete file history in our github repository: https://github.com/3Dator/3dator/tree/master/stl/extruder. Here you'll find the Step files: https://github.com/3Dator/3dator/tree/master/step/extruder. Required Parts: Push fittings 4mm M5: http://s.click.aliexpress.com/e/NRrby76 Mk7 Extruder Gear: http://s.click.aliexpress.com/e/bAAm6un MR105ZZ Bearing: http://s.click.aliexpress.com/e/amIayfE 608ZZ Bearing: http://s.click.aliexpress.com/e/fAI6UnQ Print Settings: Printer: 3Dator Rafts: Doesn't Matter Supports: No Resolution: 0.2 Infill: 20% Notes: We always print this with 3 perimeters to make it stronger. Post-Printing: To get better results with the M3 holes in extruder_base, close them with 2 layers and then open again with a drill. Bill of materials: Apart from PLA for printing the parts, you'll need the following components: 1x MR105ZZ 1x 608ZZ 1x MK7 gear for 1.75mm filament 2x M3 self-locking nuts 2x M3 40mm screws 3x M3 25mm screws 1x PTFE fitting PC4-M5 (M5 screw, for 4mm ptfe tube) 1x Nema 17 Stepper Motor Remixes: If you want to use a MK8 drive gear instead of a mk7, check out the remix of 50koruny: http://www.thingiverse.com/thing:1679553 He also added a "window" to observe what's going on inside. Instructions: Finding the right tension This Extruder supports a wide spectrum of different filaments. Usually, you only need to tighten one screw, making it easier to find the right tension. For filaments that need to be squeezed quite hard, like old PLA or Ninjaflex, you should tighten both screws. For printing Ninjaflex, you may print the Extruder Base with a nozzle as fine as possible and with a 0.1mm layer height.

With this file you will be able to print 3Dator Bowden Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3Dator Bowden Extruder.