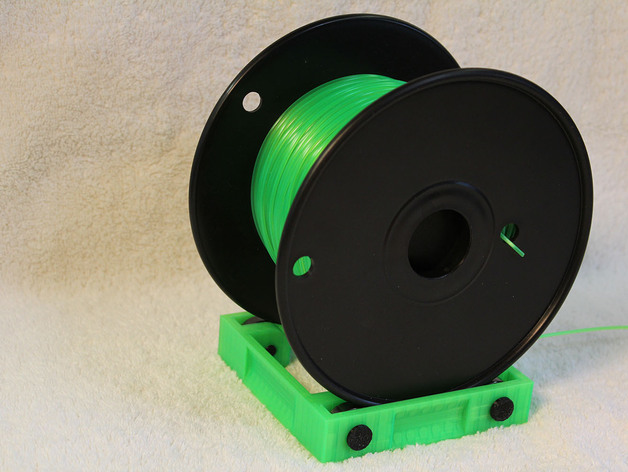

3D printer filament spool holder, fully-printable

thingiverse

This spool holder design features a rectangular peripheral frame, supporting flanges of filament spools on bearings or 3D-printed rollers. The frame is designed for upright use on horizontal surfaces with intact rigid circular flanges on the spool. To function properly, it should not obstruct any filament below the spool's flange height and ideally uses four inexpensive 608ZZ shielded skateboard bearings. The design includes 3D-printed pins to secure the bearings in the frame, which need precise sizes for a light hand press fit into the 8mm bearing bores and the frame. A bearing-sized roller design is also included, intended for a loose, low-friction fit on the pins. The holder is developed using OpenSCAD with several feature switches and is mostly parametric. For optimal performance, there should be 1-2mm clearance in excess of the spool's flange width. However, only two common frame sizes for 8" MakerBot spools (frame310, 3.10" inside frame width) and 6" wiring-type spools (frame395, 3.95" inside frame width) are included in the STL files. The designs can be customized for double bearings, wider rollers, or metric sizing by modifying parameters within the source file. Recent updates include a new version of the openSCAD source file (frameV2.scad), offering additional functionality selectable through flags in the source. New STL files have been uploaded for frames with various features and dimensions. Two .stl files are for use with MakerBot XL and XXL sized filament spools, while four others (with suffix "m" for Mini) are for different widths of 8" diameter filament spools. However, only the sizes with bearings have been tested, and it is recommended to build them with bearings due to high spool weight in XL and XXL spools, or due to reduced bearing spacing in small print beds. To assemble, pins should be 3D-printed two at a time and checked for correct diameter. If necessary, adjust the pin diameters in OpenSCAD by .05mm increments and reprint the pins. Usable 608ZZ bearings should spin freely; if not, press the bore sideways to remove any internal parts dragging on shields. The holes in the frame need light reaming by hand with sharp drill bits or hand reamers to maintain coaxiality. If rollers are used instead of bearings, their bores should be lightly reamed to remove stray filament for smooth rotation. MakerWare settings that have produced good results on MakerBot Replicator and Replicator 2 printers include .10mm layers for pins, .20mm layers for frames, and .20mm layers for rollers with rafts. Tools required are a conventional 1/4" drill bit, 5/16", 8mm or "O" drill bits, an 8mm hand reamer (optional), and a fine flat file (optional). Reaming should be done by hand without powered tools for safety. Recent updates include the ability to adjust pin diameters and frame widths slightly using MakerWare's scaling facility. Wider frames may require width adjustments in OpenSCAD or slicer software. The XXL frame needs rotation around the Z axis 90 degrees in MakerWare for printing on moderate-sized beds.

With this file you will be able to print 3D printer filament spool holder, fully-printable with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3D printer filament spool holder, fully-printable.