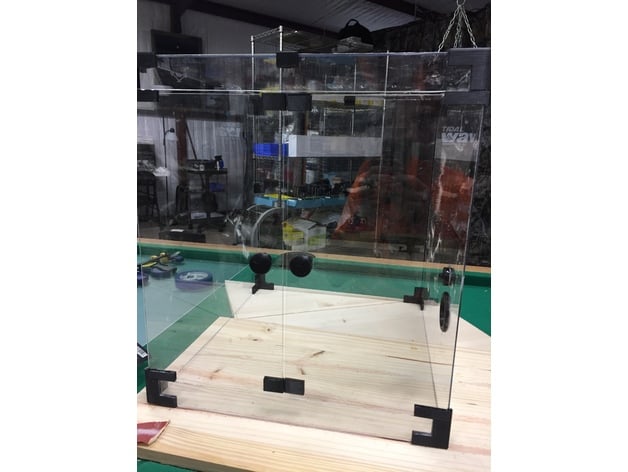

3D Printer Enclosure Reach 3D

thingiverse

I needed a custom enclosure for my 3D printer, and these two brilliant individuals generously shared their files with me, which perfectly fit the requirements of this project. Therefore, I believe it is only fitting to give them proper credit. To complete my printer, I designed additional files that can be found here, in addition to the ones provided by elkayem's and schlem's projects. Print Settings Printer: Reach 3D Printer Rafts: Doesn't Matter Supports: Yes Resolution: 0.2 Infill: 20% Notes: Most prints can be completed with a 0.2mm layer height, but some intricate parts like my knob and 2" Port may require a 0.1mm layer height for optimal detail. Post-Printing Hardware Needed: A wooden board to serve as the base. The size of the board is entirely up to you, as long as it meets your requirements for width and length. I used a 1/2" finished plywood. Wood Screws #10x3/4 pack 2mm metal rod for door hinges (available at any crafts or hardware store) Plastic Weld Epoxy Neodymium magnets 4x4mm x8 (for door latches and back plates) M5x10 x8 M5x20 x2 For knobs M5 washers 8-16 (1-2 per bolt per bracket to mount your Reach to the base) M5 T-Nuts Rubber feet for the bottom of the board x6 (optional, but recommended to prevent screws from coming loose) Printed Pieces: 2x Top Back Corners 2x Top Front Corners 4x Top Sides 2x Bottom Back Corners 2x Bottom Front Corners 2x Sides 4x Door Hinges 2x Left Door 2x Right Door 1x 2" Port and Ring 1x Swivel plug for Bowden Tube 1x Vent 8x Plexi Mounts for securing your enclosure to the wood base 4x Printer brackets to secure the Reach3D to the base (if using a different printer, you will need to design custom brackets or let it stand freely) 2x Knobs for doors (I designed a Triforce pattern on these knobs; feel free to use any knob you prefer) 2x Back plates Assembly: The beauty of this project lies in its flexibility – the size can be adjusted to your liking. Simply print the same pieces, cut your plexiglass to the desired lengths, and assemble according to your needs. Once all pieces are printed and gathered, clean out any support material. I recommend gluing pieces together in stages to ensure a seamless fit. When cutting the 2mm rod for door hinges, make sure to leave enough length for the hinges to fully seat into the corners. When attaching the back plates, press the magnets into their respective holes on the plates and doors, ensuring they face the same direction. Apply glue to the top of the plates (away from the magnets) and attach them to the front strips. Make sure the magnets align and apply pressure until it sets. Finally, secure the enclosure and printer to the board using wood screws, marking your drill points to prevent cracking. Add your knobs last, using a M5 Tap to tap the hole for the knob and securing it with an M5x20 screw. Happy printing!

With this file you will be able to print 3D Printer Enclosure Reach 3D with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3D Printer Enclosure Reach 3D.