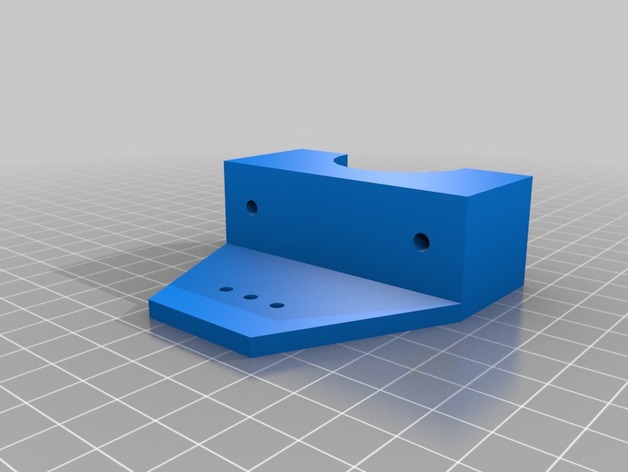

3D Printer / CNC milling Adapter

thingiverse

I'm Out of Filament - What Next? Design and Build a CNC Adapter for the REP RAP Wallace ++ (M8 Edition) 1. 50mm long M4 bolts: two are needed. 2. Four M4 washers will also be required. 3. Two M4 nuts will complete this task. The motor in question came from an older HP printer. Its model number is C4531-60012, and it operates at 24 volts. This motor has been connected to the D9 port on my Ramps 1.4 board and can be controlled using Repetier Host with CNC enabled. Print Settings: Printer Brand: RepRap Printer: Prusa I3 Rafts: Yes Resolution: .4 Nozzle PLA Infill: 70% Notes: Printed at 50% speed and 100% Flowrate PLA. How I Designed This I used Sketchup 2015 to design the adapter, then exported it as an STL. Next, I employed 3D Builder to repair any flaws in the model before saving both STL and OBJ file formats for backup purposes. Finally, I printed the part using Repetier Host Software.

With this file you will be able to print 3D Printer / CNC milling Adapter with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3D Printer / CNC milling Adapter.