3D printed lower&upper frame for Rostock Mini

thingiverse

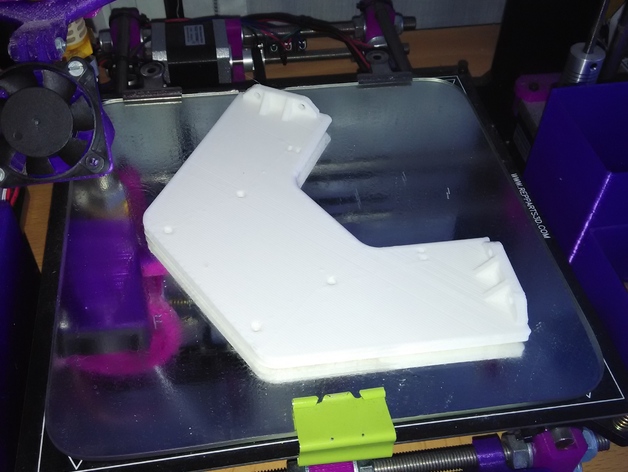

If you want to build a Rostock Mini this part could be super useful for you. It makes it easy to 3D print the upper and lower frame of your delta platform. In the original design these parts need to be laser cut, but I didn't like that idea and came up with a way to create identical frames that can be printed on any standard 20x20cm hotbed. It takes about two hours to print this piece. To build one complete frame you will need three copies of it. There are four holes in one corner for attaching the motor end or idler end - only two are actually needed, with the other two serving as spares. The piece has little pairs of holes to insert zip ties, secure wires and any other items you might need to hold in place. One side of this part is flat as a pancake, while the other has special inserts that allow you to join pieces together using M3x10 nuts and bolts. When these three copies are joined up they form a beautiful delta platform with perfectly measured proportions and a hollow center big enough for your hand to fit inside. The edges of this center part have been rounded out for an improved grip. Please keep in mind that it is absolutely essential for the piece not to bend at all - it needs to be rock-solid flat. If you don't get this just right, it can mess up how these pieces join together and spoil the entire effect. I used PLA 3mm printed with Cura using 30% infill settings to create this part.

With this file you will be able to print 3D printed lower&upper frame for Rostock Mini with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3D printed lower&upper frame for Rostock Mini.