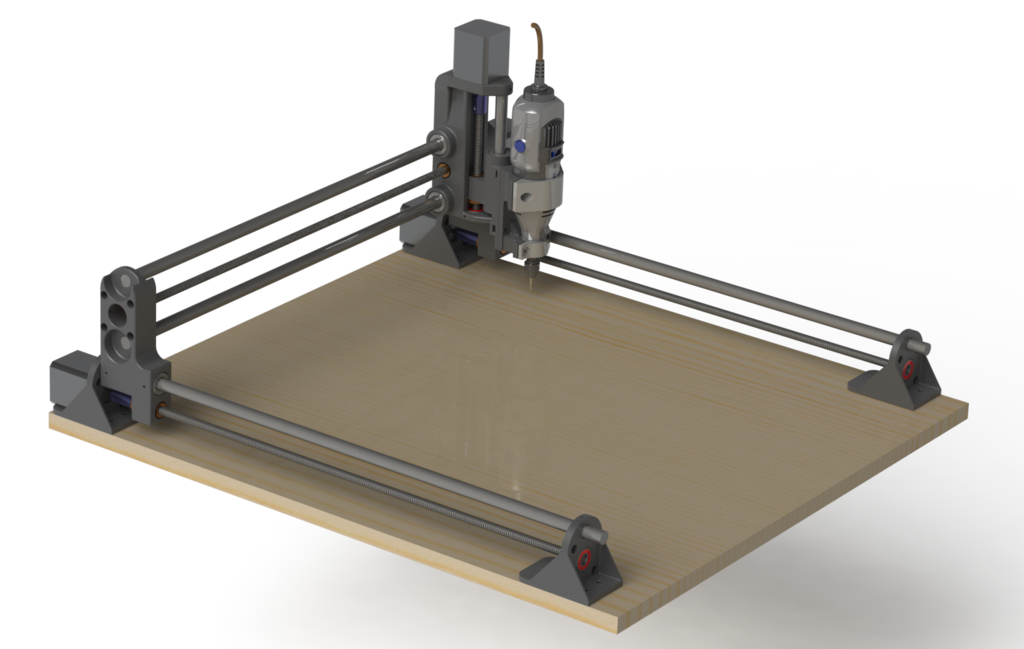

3d printed Dremel 395 CNC Mill

thingiverse

This is a redesign of Nikodem's DIY 3D printed Dremel CNC, originally designed for the Dremel 3000: https://www.instructables.com/id/DIY-3D-Printed-Dremel-CNC/ The first difference is the use of a Dremel 395 mount instead of a Dremel 3000. Secondly, the mount has been redesigned to be hinged, based on a Thingiverse model by "dintid": https://www.thingiverse.com/thing:1761641 Thirdly, the mount is now removable and replaceable, allowing for easy swapping between a pen or laser etching module and the Dremel cutter. Fourthly, I have eliminated the square 20mm extrusion frame, as it does not provide any benefits over the MDF base. Instead, I built the gantry to align and locate the bottom four feet. Fifthly, both X and Y leadscrews were lengthened to 500mm, allowing for a total travel of approximately 465mm on each axis (axial travel is optimized to be about 93% of the total screw length). Sixthly, I have doubled up the linear bearings on all three axes - X, Y, and Z - for greater support. There are now a total of 10 high-precision linear bearings. Note that installing these bearings back-to-back requires honed holes to ensure proper alignment; otherwise, they will inevitably drag fiercely on the rods. However, as this is not possible with 3D printing, I have had to compromise and use only five bearings at their farthest distance for maximum stability. Seventhly, I have replaced ordinary leadscrews with anti-backlash leadscrews, which offer improved accuracy and repeatability at a slightly higher cost. Note that I also changed the lead from 8mm to 2mm and switched from 16th microstepping to quarter microstepping (still 400 microsteps per mm travel). High microstepping can reduce motor torque, but with 2mm lead, motors turn four times as much for the same distance, which can be slower. I have found that cutting at speeds above 200 mm/min can damage mill bits, so I now cut at significantly lower rates. Eighthly, I revised the Z-axis to use a single 12mm linear rod, allowing the carriage to become narrower. Ninthly, the Z-axis now has a total range of 65mm. The bit cannot go below the base or above the bottom of the gantry, ensuring that it does not damage the base and can clear workpieces up to 65mm tall. Note that I included a 3D printed coupling model, but these do not perform well in practice. My photos show solid aluminum couplings, which also perform poorly due to screw shaft warping and misalignment. To achieve better results, I have resorted to purchasing compliant couplings instead of relying on 3D printing.

With this file you will be able to print 3d printed Dremel 395 CNC Mill with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3d printed Dremel 395 CNC Mill.