3D Filament Splicer

thingiverse

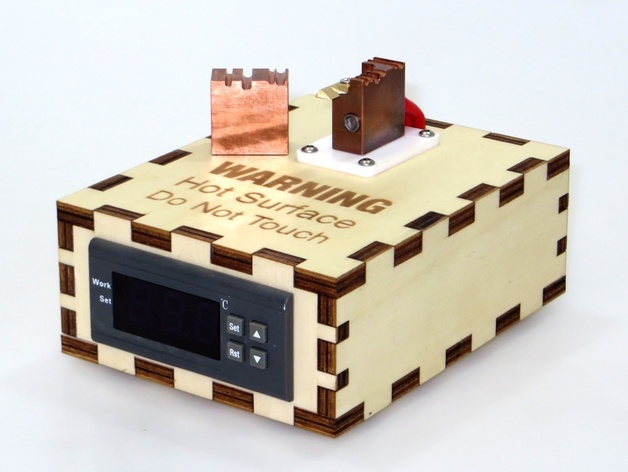

Introducing a tool for splicing 1.75 and 3mm 3D filaments, designed with manual labor in mind due to issues like expansion/shrinkage. Results show improved joint quality using the splicer compared to manual methods. This 'little thing' took quite some effort; get the copper parts, kit, or fully assembled unit through our crowdfunding campaign. We aim for more color options in OSS 3D printing and have other ideas in store, with the Filament Splicer being just a starting point. For assembly, you need a 6mm plywood frame (blueprint available), Teflon thermal isolation plates, copper heating/cooling blocks (also blueprinted), a 12v thermal controller from Willhi, a 300°C thermal probe with a 4mm diameter, a cartridge heater, a 12v 5mm socket, an on/off switch with a 12mm neck and M3 terminal screws, a 12v 6A power supply, 0.5 mm2 wires, 4 x 20mm M3 screws with matching bolts, 2 x 7mm M5 screws with countersunk heads, 2 crimp-on 3mm terminals (optional for switch connector), wood glue, rubber feet, and a brass profile for the hot knife fixation (optional). Note the M3 hole on the heating block is for the hot knife and should have a V-Groove. The thermal isolation plate for the heating block should also have a drilled impression for the countersunk screw head. Assemble the box with wood glue, and protect it with oil to prevent dirt accumulation. Be cautious not to exceed 260°C when using the Teflon plates to avoid nasty fume emissions.

With this file you will be able to print 3D Filament Splicer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3D Filament Splicer.