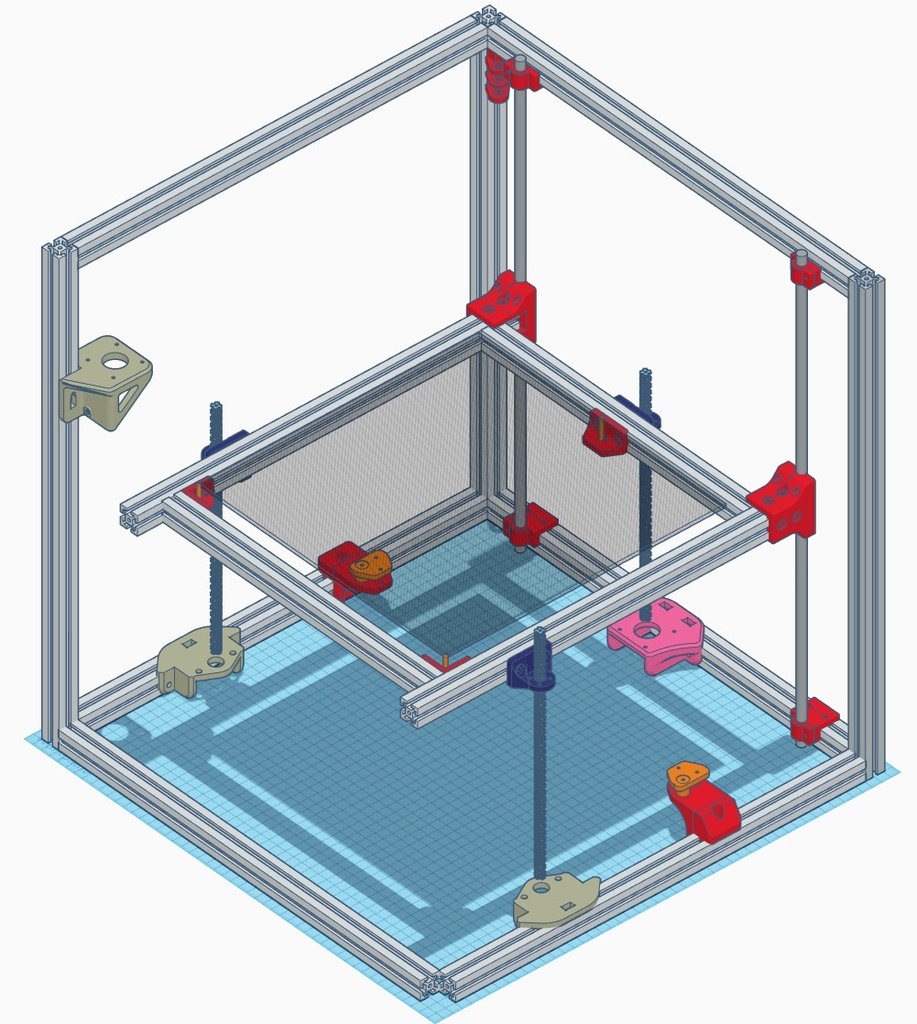

3 motor or belted Leadscrew design for Hypercube 300

thingiverse

This is a Hypercube 300 redesign utilizing three leadscrews and two support rods. It eliminates center side extrusions and long rod supports, instead moving rods to outside corners on the rear [and front] sides. \r\n\r\nMay 9 - The redesigned rod clamps now mount to the side of the extrusion rather than the bottom, significantly increasing stability. \r\n\r\nThe bed mounting brackets are updated to attach to the sides instead of the bottom, with corner mounting brackets included for beds with four mounting holes. \r\n\r\nReused 410mm 2020 bed extrusions require two 320mm pieces for the new bed frame design and either two or four rods spanning between top and bottom extrusion lengths, such as 500mm in my case. \r\n\r\nBearing cap plates can be downloaded from Sturdy HyperCube Z Carriage (in remix sources) or repurposed existing Z axis bearing holders to move rods outside instead of aligned with bed extrusions. \r\n\r\nMotor and pillow bearing mounts are available for download from Improved Z-Lead Screw Mounts (in remix sources). \r\n\r\nIn addition, 8mm and 10mm rod Z joiners have been included; if needed, find or build your own 12mm joiners. My bed is remarkably stiff with three leadscrews and two 8mm rods, making larger rods unnecessary. \r\n\r\nTo use four rods instead of two, simply duplicate the rear parts to the front side, utilizing existing 2020 extrusions from the original bed design for front-to-back Z joiners.

With this file you will be able to print 3 motor or belted Leadscrew design for Hypercube 300 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 3 motor or belted Leadscrew design for Hypercube 300.