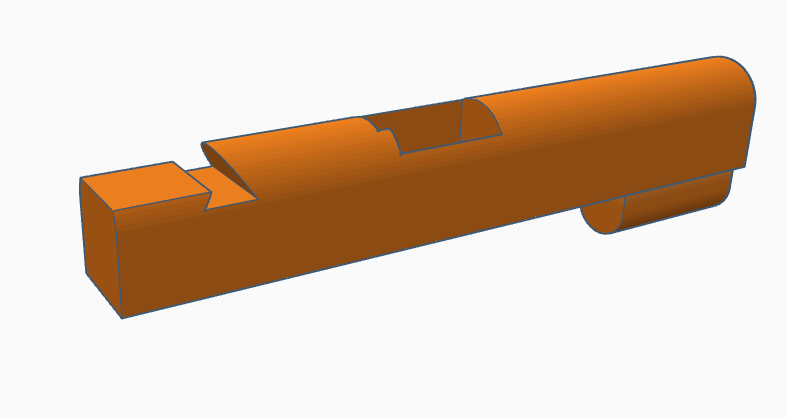

1911 Novak sight and charging handle cutting jig

thingiverse

https://youtu.be/U0EH4mVR2Ro The dimensions for the slide cuts were found online at the 1911forum. The measurements for the jig were taken from an unfinished Wilson Combat 1911 Government slide. If you choose to use this jig before I have tested it on my own slide do so at your own risk. PLEASE READ INSTRUCTIONS BEFORE USE FOR BEST RESULTS I'm using these jigs to file novak style sight cuts into my Wilson Combat 1911 slide to use on a 3011 carbine build. Since no one offers a side charging handle for novak style sight cuts I designed a couple jigs that would allow you to file a piece of 1/2" or 3/4" round stock to fit the novak sight cuts to use as a side charging handle. Jigs 1, 2, and 3 are for filing the 65 degree angle into your round stock. The drilling jig is for drilling a 2.5mm hole into the dovetail so that it can be tapped with a M3 tap, then install a set screw to prevent the charging handle from walking out. I have the stick out for filing set to 0.5", most slides are right around 0.925" wide so you will have to file the first half inch then adjust the stick out so that you can file the rest of the dovetail to your needed length. This allows you to use a safe edge file without damaging the jig so that your cuts are more precise. They are intentionally made to leave an oversized dovetail so that you can do final fitting to match your slide. SLIDE CUTTING INSTRUCTIONS 1) put your slide into the jig. 2) clamp your jig into a vise 3) remove material from the rear of the slide until it's flush with the jig 4) use a narrow file to remove material from the center of the dovetail until it's flush with the jig IMPORTANT: the width of your file MUST be less than 0.240 inches 5) using a narrow file, start to widen the base of the dovetail until it is close to the jig 6) using a triangle file, finish the edges of the dovetail NOTE brownells sells safe edge files specifically for cutting novak sights that will give you the correct angles, they feature a safe edge on the bottom so that you don't accidentally increase the depth of the dovetail. 7) optional, use a finish file or diamond file to smooth out your cuts, do not remove any more material than necessary. the smoother the finish the easier installation of sights or charging handles will be CHARGING HANDLE INSTRUCTIONS 1) print the jigs 2) install a M3 heat set threaded insert into the side tube of the jigs 3) insert your round stock into the jig so that it is flush with the beveled end 4) tighten your M3 bolt to hold the round stock in place 5) use a marker or scribe to note the alignment on the top and bottom of your round stock 6) using a flat, pillar, or equalling file remove material from the round stock until it is flush with the bevel in the jig 7) loosen your M3 bolt and push the bar stock farther into the jig until you have the desired amount of material for your slide 8) file the material until it's flush with the jig 9) repeat for jigs 2 and 3 10) when you have the appropriate length dovetail for your slide use calipers to find the center on the bottom of the dovetail. mark it with paint or a marker. 11) insert your round stock into the drilling jig until your mark is lined up with the drilling port. 12) tighten the M3 screw and drill all the way through your round stock 13) remove the bar stock from the drilling jig and tap it with a M3 tap 14) using a fine cut file or diamond file finish fitting your charging handle to the slide 15) optional, put the dovetail into a 1/2" drill, loop sandpaper over the charging handle, and spin the drill to smooth out the surface and remove any burrs or edges left by the M3 bolt 2/23/2022 - changed the dimensions of the 750 charging handle jigs to fit raw round stock better, the originals were a little bit too tight and were prone to breaking. the 500 charging handle jigs will likely need changed as well but I haven't had a chance to test them yet. 3/16/2022 - adjusted the dimensions of the charging handle jigs and the slide jigs. The 500 jigs are untested. There are 2 slide jig files, either will work but I prefer using the 240 jig while filing the flat top onto the slide. This top cut can be done primarily with a rough cut file then cleaned up with a finish cut file. This will reduce the amount of filing depth you need with small files for the dovetail. Get a rough cut in your dovetail leaving extra material at the bottom initially, as it's very easy to go too deep while widening the dovetail. If you notice that you are filing into the jig stop and print a new one, this will help keep everything in tolerance.

With this file you will be able to print 1911 Novak sight and charging handle cutting jig with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 1911 Novak sight and charging handle cutting jig.