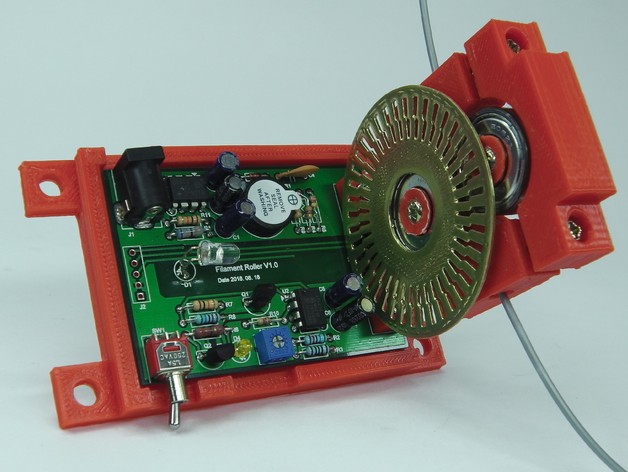

1.75mm Inline Filament Roller IR Sensor Version 3

thingiverse

A Kickstarter campaign for this innovative product is now live: https://www.kickstarter.com/projects/522476987/filament-roller. Make a donation and receive a completed Filament Roller, showcasing your support. This is a cutting-edge IR sensor and alarm designed to detect the direction and speed of 1.75mm filament spools. The sensor will sound an alarm when the spool stops due to: filament-jamming, nozzle-clogging, extruder-grinding, motor-stalling, out-of-filament, or end-of-print. If your filament stops moving forward, this sensor will detect it and alert you promptly. This third version is a compact model designed to fit inline with your filament, close to the extruder. It's specifically designed for 1.75mm filament spools. Required parts include: 608 ball bearings (2 ea), M3 x 12mm screws (4 ea), M3 x 18mm screws (2 ea), M3 nuts (6 ea), Filament Roller control board (1 ea), and small rubber bands (1 ea). Printer Settings: Printer: no name i3 clone Rafts: No Supports: No Notes: This device is relatively easy to print. Post-Printing Instructions: The Roller After printing the roller, you should apply a coat of paint so it can effectively block IR light. Once the paint dries, insert the bearing and slip on the rubber band. A painted roller Assembly Instructions: 1) Insert a bearing cap and screw the roller into the pylon using an M3 x 12mm screw. 2) Insert a bearing cap and screw the counter-bearing together using an M3 x 12mm screw. 3) Screw the pylon to the PCB and case using M3 x 12mm screws. 4) Screw the counter-bearing assembly to the pylon using M3 x 18mm screws. Powering the Board For powering the board, you can use a 5-24V DC wall adapter. The DC jack should have a 5.5mm outer diameter and a 2.0 or 2.1mm inner diameter. Alternative Power Sources Alternatively, you can power the board directly by connecting it to your 3D printer's SMPS. However, do not simultaneously connect a wall adapter and SMPS power to the board at the same time. This is hazardous and can permanently damage your equipment. Using the Board To control the alarm delay, adjust the control knob on the PCB. In the example shown below, the delay is set to 21 seconds and the forward direction of the roller is set to counter-clockwise (anti-clockwise). Questions and Support If you have any questions or need assistance, feel free to post in the comments.

With this file you will be able to print 1.75mm Inline Filament Roller IR Sensor Version 3 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on 1.75mm Inline Filament Roller IR Sensor Version 3.